Start Your Die Casting Project Today

Shine-Choose specializes in aluminum, magnesium, and zinc alloy die casting. Get your free consultation & quotation now.

Shine-Choose Services

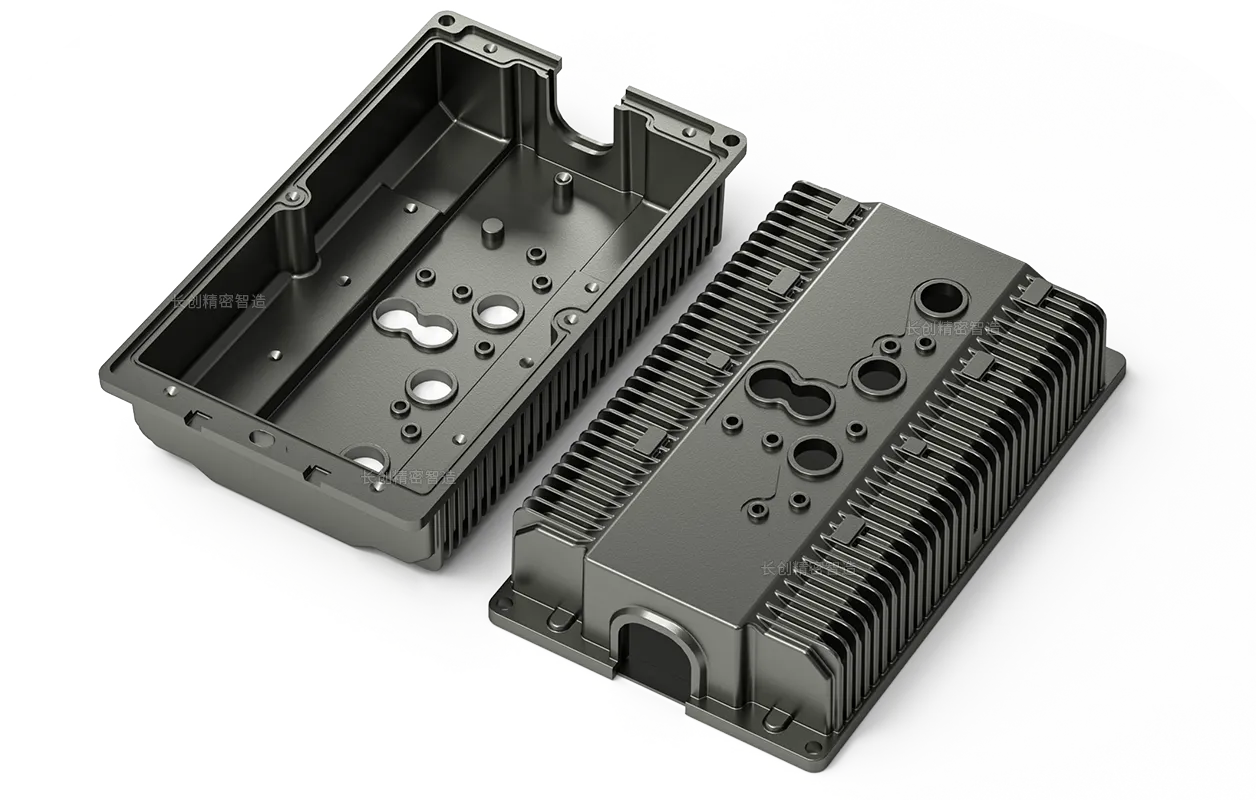

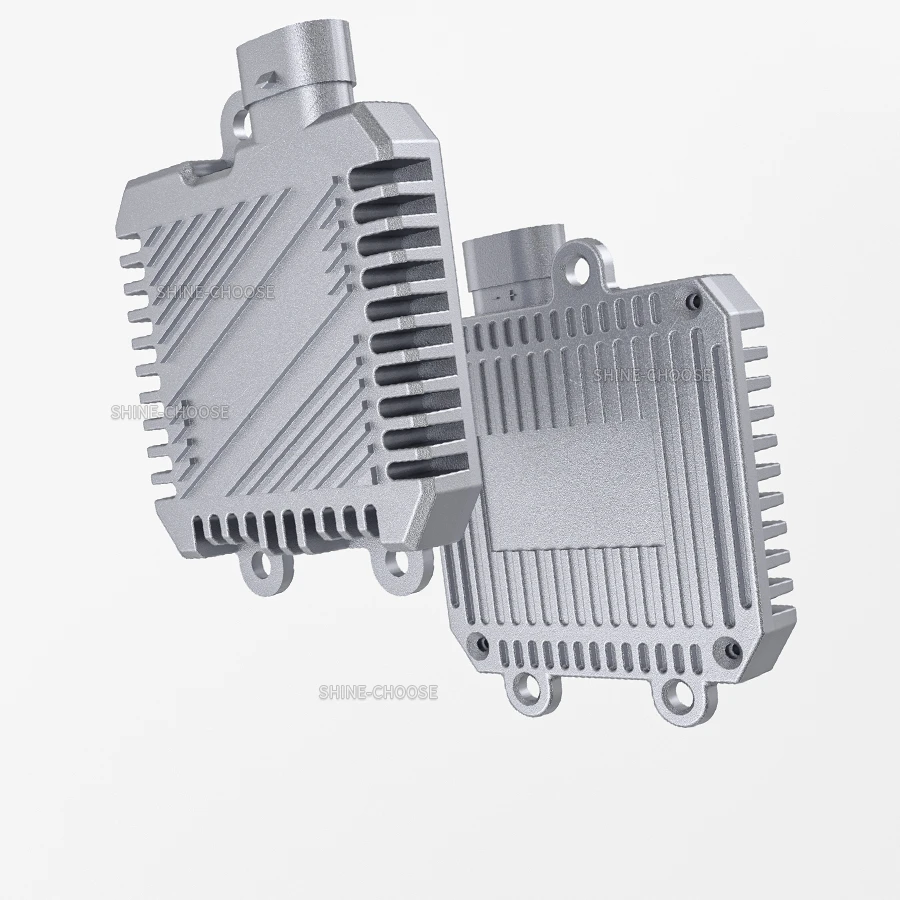

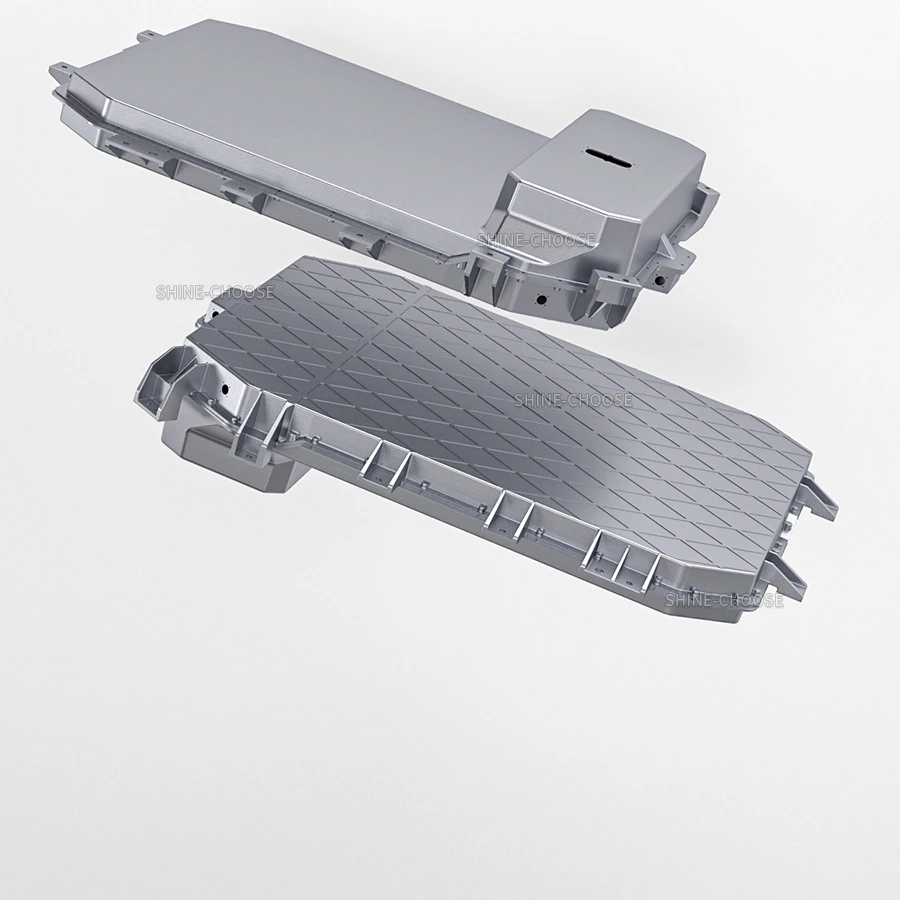

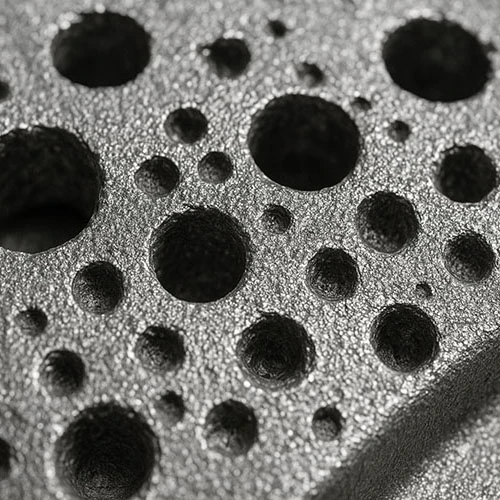

Contact UsAluminum Die Casting

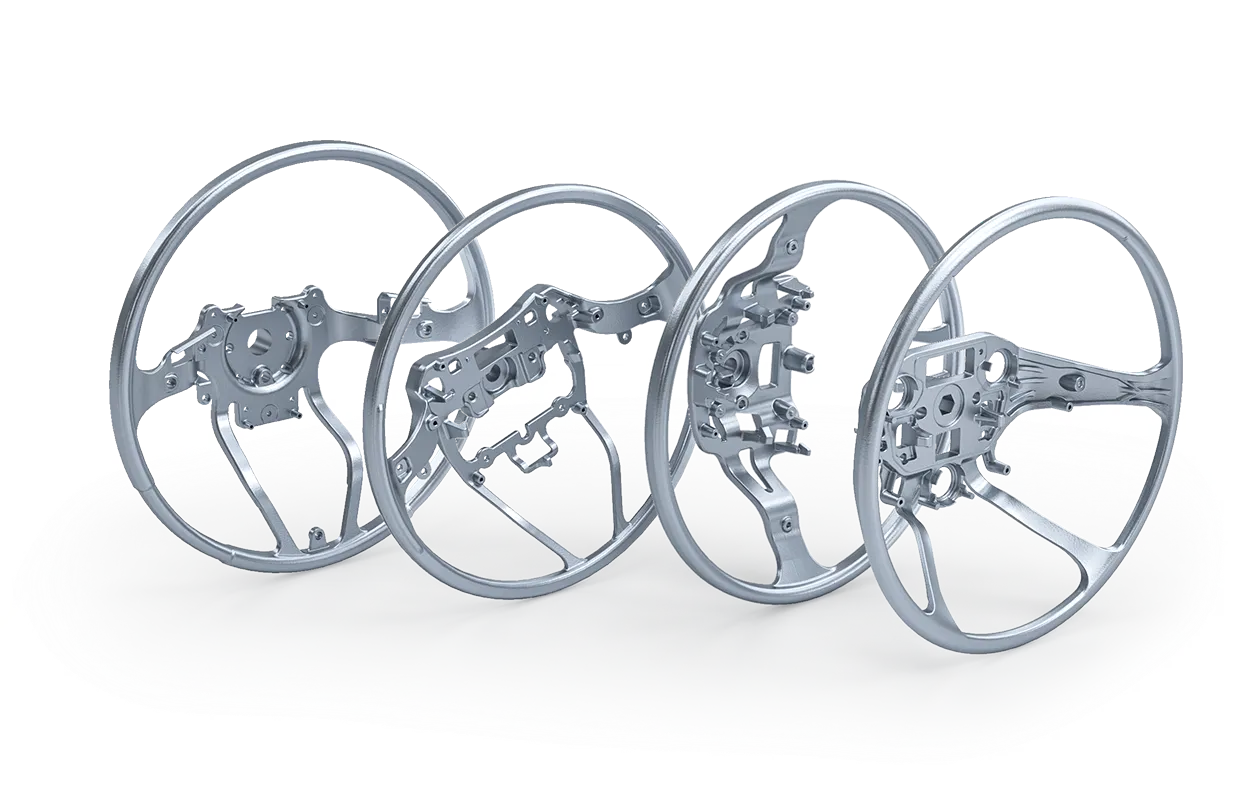

Read MoreMagnesium Die Casting

Read MoreZinc Die Casting

Read More

Drawings to Reality - 17 Years of Custom Manufacturing

Custom magnesium, aluminum & zinc alloy parts - from precision small components to die-cast parts up to 1 meter.

17

17 Years Manufacturing

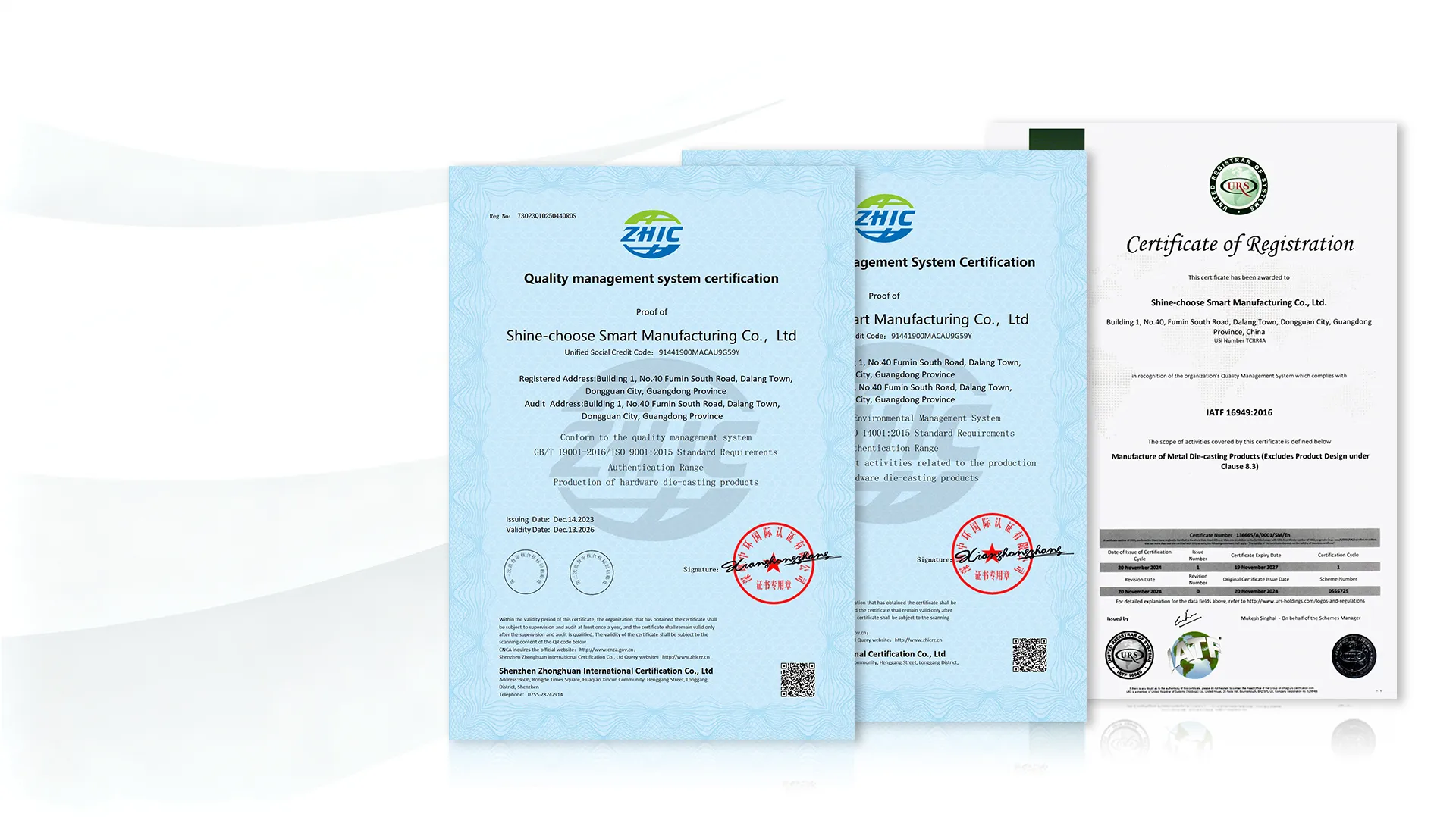

Quality Guaranteed | Certified Manufacturing

Precision Manufacturing is certified with ISO 9001 Quality Management, ISO 14001 Environmental Management, and IATF 16949 Automotive Quality Management Systems.

ISO 9001

Certified

ISO 14001

Certified

IATF 16949

Certified

Reliable Lead Times, No Delays

Molds are ready in 25 days, samples in 3 days, and mass production in 7 days. One-to-one 24/7 service with full production progress tracking.

25 Days

Mass production molds

2 Days

Quick proofing

Capability in Zinc, Aluminum, and Magnesium Alloy Die Casting Production

Equipped with die-casting machines ranging from 55 tons to 1250 tons.

55-1250T

Die casting machine tonnage

Manufacturing Process Display

Contact UsShine-Choose Smart Manufacturing Co., Ltd

Custom manufacturer of zinc, magnesium, and aluminum alloy die-cast components.