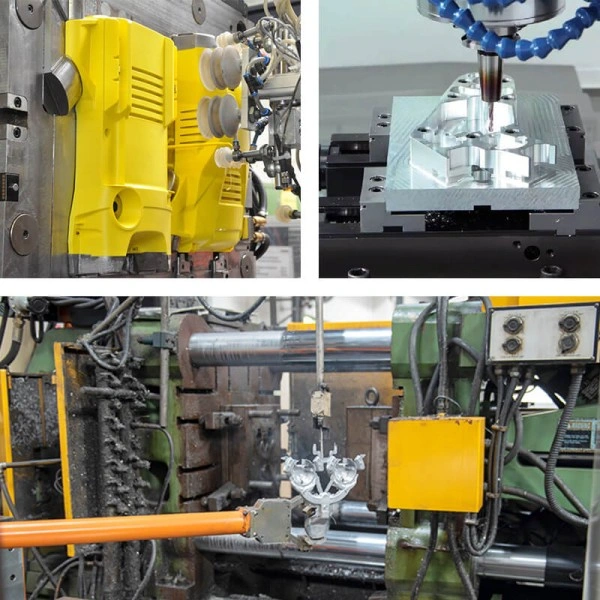

This article presents several die-casting case studies manufactured by Shine-Choose. These examples illustrate the typical applications and core performance requirements of zinc-, aluminum-, and magnesium-alloy die-cast parts. This content helps product developers, engineers, and procurement teams to understand better material selection, performance targets, and cost-performance balance.

EV Battery Pack Enclosure – Magnesium Alloy Die Casting

Application:

Used as the battery pack housing in electric vehicles. One-piece lightweight structural design for core protection and structural reinforcement of the battery system.

Typical Requirements:

- Optimized wall thickness control to balance structural strength and metal flowability.

- Lightweight design to reduce energy consumption and improve driving range.

- Excellent thermal conductivity for efficient thermal management.

- Anodizing or coating for improved corrosion resistance and cosmetic quality.

Automotive Steering Wheel Frame – Magnesium Alloy Die Casting

Application:

The core support frame for the automotive steering wheel, replacing traditional steel frames, is widely used in new energy and high-end vehicles.

Typical Requirements:

- Must withstand continuous load, vibration, and long-term usage.

- Excellent salt-spray and corrosion performance with anodizing or coating.

- High dimensional accuracy to ensure perfect assembly with steering wheel cover and airbag module.

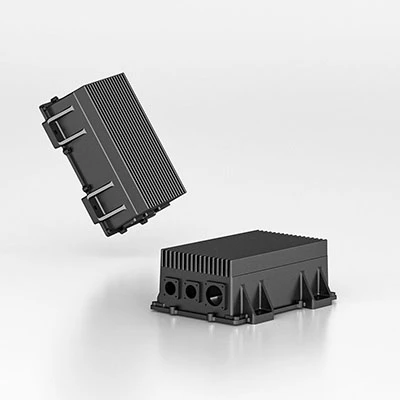

DCDC Converter Housing – Aluminum Alloy Die Casting

Application:

Used for voltage management and isolation inside vehicle electrical systems. A key component for power distribution in new energy vehicles.

Typical Requirements:

- Superior heat dissipation performance.

- Excellent structural protection with vibration and shock resistance.

- Precise CNC-machined mounting interfaces and sealing grooves for leak-free connection with wire harnesses and connectors.

- Protection level may include IP-rated dustproof and waterproof.

- Surface treatment customized per installation environment (e-coating, powder coating, etc.).

Automotive Ballast Housing – Aluminum Alloy Die Casting

Application:

Housing for automotive headlamp ballast electronics, suitable for xenon and LED automotive lighting systems.

Typical Requirements:

- High structural strength and dimensional accuracy.

- Excellent thermal performance to dissipate heat generated by power devices and transformers.

- Surface treatment with insulation and corrosion resistance.

Zinc Alloy Housing for Handheld Beauty Device

Application:

High-end handheld beauty device exterior enclosure, premium appearance carrier.

Typical Requirements:

- Zinc alloy provides a premium weight and texture.

- Anodizing can achieve various finishes, such as Champagne Gold, Space Gray, and Rose Gold.

- The die-casting process supports complex surface details, including delicate patterns and logo features.

Quadcopter Frame – Magnesium Alloy Die Casting

Application:

Structural frame for quadcopters, supporting motors, batteries, and control modules. Widely used in consumer drones and industrial UAVs.

Typical Requirements:

- Ultra-lightweight design to extend flight endurance.

- High structural strength and fatigue resistance to handle vibration and air pressure impact.

- Critical dimensional accuracy for motor mounting interfaces to prevent resonance.

- Anodizing or coating for corrosion and wear resistance for outdoor use.

Automotive Water Pump Housing – Aluminum Alloy Die Casting

Application:

Used in vehicle cooling systems to connect engine/cooling channels and the impeller, suitable for ICE, hybrid, and EV motor cooling systems.

Typical Requirements:

- High structural strength to withstand fluid pressure.

- High sealing reliability with precisely machined sealing grooves and assembly planes.

- Aluminum alloy provides excellent thermal conductivity.

- Precise tolerance coordination with impeller and bearings.

- Corrosion resistance with phosphating or e-coating surface treatment.

A-Pillar Mirror Mounting Bracket – Aluminum Alloy Die Casting

Application:

Structural mounting bracket between the A-pillar and the side rear-view mirror for passenger cars and commercial vehicles.

Typical Requirements:

- High structural stiffness to resist wind load and vibration.

- Lightweight design to reduce unsprung mass and improve vehicle handling.

- Precise bolt hole and locating pin tolerances for stable mirror angle.

- Color-matching coating with strong salt-spray corrosion resistance for outdoor environments.

Conclusion

Zinc, aluminum, and magnesium alloys each offer specific material advantages: zinc delivers a premium surface finish and fine detail, aluminum provides excellent heat dissipation and corrosion resistance, and magnesium offers the best lightweight strength-to-weight ratio. Shine-Choose provides full-service OEM/ODM support from material selection, DFM, and tooling development through to mass production to help our customers achieve the best balance between performance and cost.