1. Pain Points of Plastic Frames: Why Switch to Magnesium?

As the primary load-bearing component, the drone frame plays a crucial role in overall performance. However, traditional plastic injection-molded frames (typically ABS or PA) face three significant limitations:

- Lightweighting Bottleneck – To maintain sufficient strength, wall thickness must be increased. As a result, the frame weight often accounts for 15–20% of the total UAV weight, directly shortening flight endurance (e.g., a 100g plastic frame can reduce flight time by 5–8 minutes).

- Poor Impact Resistance – Drop tests from 1.5m show residual deformation of 1.2–2.0mm for ABS/PA parts, with occasional fracture in structural areas. After multiple flight cycles, the failure rate rises sharply, and after-sales maintenance costs can reach 8–15%, even higher in high-frequency applications.

- Limited Service Life – Long-term loading and UV exposure lead to material aging; fatigue life is only 1/5–1/10 that of metal parts (per the Mold Engineering Handbook, 2019 Edition), making plastic frames unsuitable for professional-grade drones.

By contrast, magnesium die casting offers an ideal alternative, combining lightweight, high strength, and durability to overcome these limitations.

2. Core Advantages: Magnesium Alloy vs. Plastic — Performance Comparison

| Performance Parameter | Plastic (ABS/PA) | Magnesium Alloy (AZ91D) (ASTM B94) |

|---|---|---|

| Density (g/cm³) | 1.05–1.2 | 1.8 (~1/3 lighter than aluminum, 23% lighter than plastic for equivalent strength) |

| Tensile Strength (MPa) | 40–70 | 230 (~5× stronger than plastic) |

| Fatigue Life (cycles) | 10⁴–10⁵ | 5×10⁵–8×10⁵ (5–8× longer lifespan) |

| Thermal Conductivity (W/m·K) | 0.2–0.3 | 75 (~375× higher; significantly improves heat dissipation from battery compartment) |

3. Feasibility Analysis: When Does Magnesium Make Sense?

1. Recommended Scenarios

- Long-Endurance UAVs – Surveying and inspection drones benefit from the magnesium alloy’s low density (1.8g/cm³), providing a 12–15% increase in flight time compared with plastic frames.

- High-Impact Environments – Consumer drones with magnesium frames withstand 1.5m drop tests with ≤0.5mm deformation and no cracking, ensuring higher reliability.

- Complex Structural Components – For multi-cavity battery housings or integrated brackets, magnesium die casting offers excellent fluidity and yields 85–95%, minimizing assembly errors.

2. Technical Challenges

- Tooling Cost – Initial tooling investment for magnesium die casting is 30–50% higher than plastic injection molds, but unit cost drops 15% after 100,000 shots due to amortization.

- Design Adaptation – Wall thickness should be reduced by 10–15% compared with plastic, with a draft angle ≥3° to prevent shrinkage porosity or ejection issues.

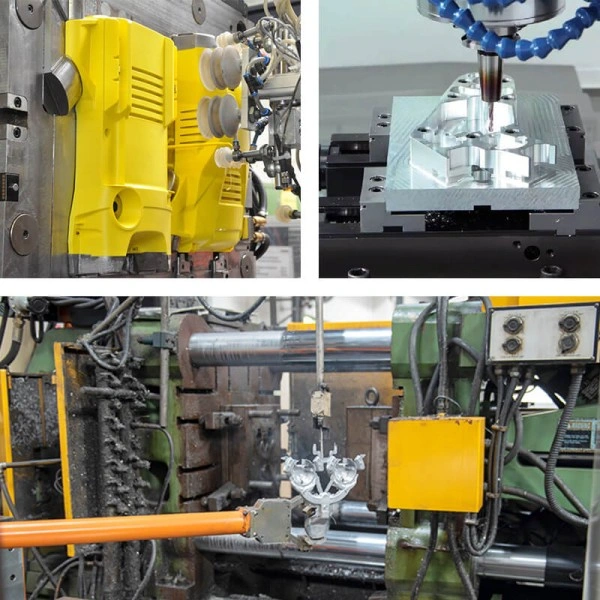

4. Implementation Essentials: From Design to Mass Production

1. Design Optimization

- Structural Integration – Combine multiple plastic components (e.g., a bracket and a battery housing) into a single magnesium die-cast structure, reducing the part count by up to 30%.

- Rib Reinforcement – Decrease rib thickness by 10–15% (e.g., from 1.5mm → 1.2mm) to further reduce weight while maintaining stiffness.

2. Process Control

- Die Casting Parameters – Melt temperature: 580–620°C, mold temperature: 180–220°C, injection velocity: 3–5 m/s, ensuring stable filling and reduced thermal stress.

- Surface Treatment – Apply Micro-Arc Oxidation (MAO) for enhanced corrosion resistance. Salt spray test performance improves to 500 hours compared with 200 hours for plastics.

3. Cost Optimization

- Production Threshold – For annual volumes above 50,000 units, the total cost (including tooling, material, and machining) is 8–12% lower than plastic.

- Supplier Selection – Partnering with die-casting foundries experienced in UAV applications can reduce mold trial cycles by 30%, thereby minimizing prototyping costs.

5. Case Study: Proven Performance in Real Applications

A commercial UAV manufacturer upgraded its plastic frame to magnesium die casting, resulting in:

- Weight Reduction – Frame weight decreased from 100g → 77g (−23%), improving total flight endurance from 25 min → 29 min (+16%).

- Reliability Improvement – Drop test cycles increased from 300 → 500, while after-sales failure rate fell from 20% → 5%.

- Cost Efficiency – After ramp-up, per-frame production cost was 12% lower than the previous injection-molded version.

Conclusion: The Strategic Value of Magnesium Die Casting in UAV Frames

Transitioning drone frames from plastic injection molding to magnesium die casting delivers transformative benefits through:

- Lightweight Design – Density only 1.8g/cm³

- High Strength – Tensile strength up to 230 MPa

- Extended Durability – Fatigue life 5–8× that of plastic

By focusing on optimized design (thin walls, draft angles), process control (die-casting parameters), and volume-cost balance, UAV manufacturers can achieve higher endurance, robustness, and production efficiency—making magnesium die casting the preferred solution for long-endurance and high-impact drone applications.

(Data references: Mold Engineering Handbook, 2019 Edition; ASTM B94 Magnesium Alloy Standards; UAV Manufacturer Test Reports.)