In manufacturing, 6061 aluminum alloy is widely used for its balanced mechanical properties. In contrast, ADC12 aluminum alloy die-cast parts are commonly considered alternatives due to the die-casting process’s high efficiency and ability to produce complex geometries. However, a material substitution is never a simple swap; it must be evaluated comprehensively based on performance, process capability, and application conditions.

This article analyzes whether 6061-machined parts can be replaced by ADC12 die-cast parts, detailing the key engineering considerations and scenarios where conversion is not recommended.

1. First Step: Understand the Fundamental Differences Between ADC12 and 6061

Although both are aluminum alloys, their material characteristics and manufacturing processes differ significantly—this is the foundation of evaluating feasibility.

ADC12: A “high-efficiency” aluminum die-casting alloy

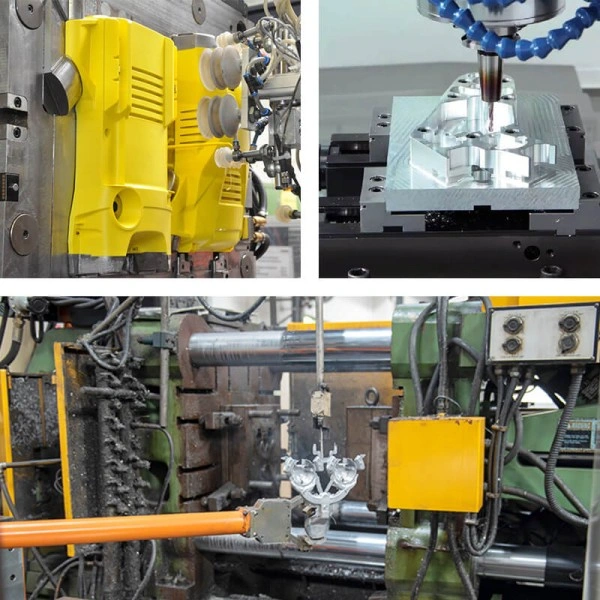

A standard alloy for high-pressure die casting (HPDC), ideal for near-net-shape complex components such as cylinder head covers or sensor brackets. Its high silicon content (9.6%–12%, per GB/T 15114-2021) provides excellent melt fluidity, enabling stable filling in thin-wall and complex cavities. However:

- Low ductility (elongation 3%–5%)

- Poor weldability

- Possible surface issues after machining due to silicon precipitation (e.g., grey powdery appearance)

6061: A “multi-performance” wrought aluminum alloy

Produced mainly via extrusion and then CNC-machined to final precision. Key advantages include:

- Excellent machinability (suitable for precision milling, drilling, tapping; achievable tolerance ±0.01 mm, IT5)

- Excellent weldability (joint strength up to 85% of parent metal)

- Mg content (0.8%–1.2%) delivers superior corrosion resistance (neutral salt spray ≥500 hrs per ISO 9227)

- High toughness (elongation ≥12% in T6 condition)

2. Three Critical Factors Before Replacing 6061 with ADC12 Die Casting

1) Mechanical Performance Compatibility

Toughness & Load-Bearing

6061 has significantly higher ductility than ADC12 (12% vs. 3–5%). If the product experiences dynamic loads or impacts, such as:

- Drone frames

- Robotic joints

- Structural brackets

ADC12 (brittle, low-impact strength) may crack or fail.

Corrosion Resistance

6061 performs significantly better in harsh environments:

- Outdoor

- High humidity

- Mild acid/alkali

- Marine atmosphere

ADC12 typically survives only 100–200 hours of salt spray before corrosion initiates.

Surface & Post-Treatments

6061 is suitable for:

- Hard anodizing

- Decorative anodizing

- High-adhesion electroplating (up to 5B per ASTM D3359)

ADC12 is not stable in anodizing due to high silicon content, commonly resulting in:

- Patchy color

- Darkened surface

- Inconsistent coating thickness

This is critical for consumer electronics housings, optical components, and related components.

2) Process Compatibility: Die Casting vs. CNC Machining

Structural Complexity

ADC12 Die Casting: Best for complex 3D geometries, thin walls, integrated structures, and near-net-shape components. Cycle time ≤30 seconds; material utilization >95%.

6061 Extrusion + CNC Machining: Best for linear or profile-based geometries.

If the original 6061 part is simple, switching to ADC12 may increase tooling costs—die-casting mold costs usually range from USD 20,000–50,000+.

Machining Accuracy

6061 is suitable for:

- High-precision milling

- Boring

- Tapping

- Surface finishing up to Ra0.4µm

ADC12 (HPDC) usually achieves:

- Dimensional accuracy IT6–IT8

- Natural casting tolerance ±0.1–0.3 mm (GB/T 6414)

- Possible porosity, shrinkage cavities, flash

Not suitable for high-precision components unless additional CNC machining is added.

3) Cost & Production Volume

ADC12 is cost-effective for large-volume production (≥500,000 pcs/year).

6061 is more economical for small–medium batches due to low tooling cost (extrusion dies ~USD 1,000–3,000).

If the volume is small, switching to ADC12 may increase the total cost due to the expense of die-casting tooling.

3. Three Application Scenarios Where ADC12 Cannot Replace 6061

1) High-Impact / Structural Load Applications

Examples:

- UAV frames

- Automotive suspension parts

- Mechanical transmission components

6061 absorbs impact energy (Charpy V-notch ~10 J), while ADC12 often fails at 2–3 J.

2) Parts Requiring Welding

6061: Excellent weldability (porosity <1%).

ADC12: High silicon causes severe porosity (5–10%), cracks, and weak joints (180–220 MPa vs. 6061’s ~310 MPa).

Therefore unsuitable for:

- Frame welding

- Tube–tube joints

- Pressure vessels

- Structural assemblies

3) Precision Parts or High Corrosion-Resistance Components

Examples:

- Medical device components (must withstand repeated sterilization)

- Marine hardware

- Precision instrument housings

- High-gloss anodized surfaces

ADC12 fails in corrosion, plating, and high-precision requirements.

4. Summary: The “Golden Rule” of Substitution

Switching from 6061 to ADC12 only works when:

- ✔ Complex geometry

- ✔ Large-volume production

- ✔ Low welding/corrosion requirements

- ✔ Moderate structural load

Do not replace if the application involves:

- ✘ Impact load / structural strength

- ✘ Welding

- ✘ High-precision machining

- ✘ Marine/harsh environments

- ✘ High-end surface finishing (anodizing/electroplating)

Engineering validation (strength test, salt spray test, surface-treatment test) is recommended before mass production.