The Requirements for Anodizing

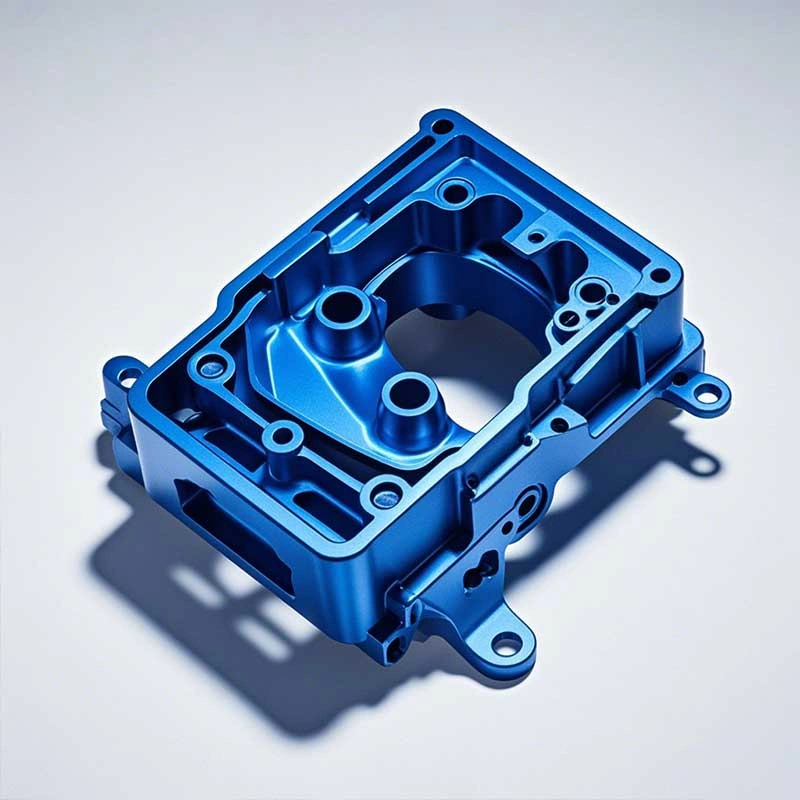

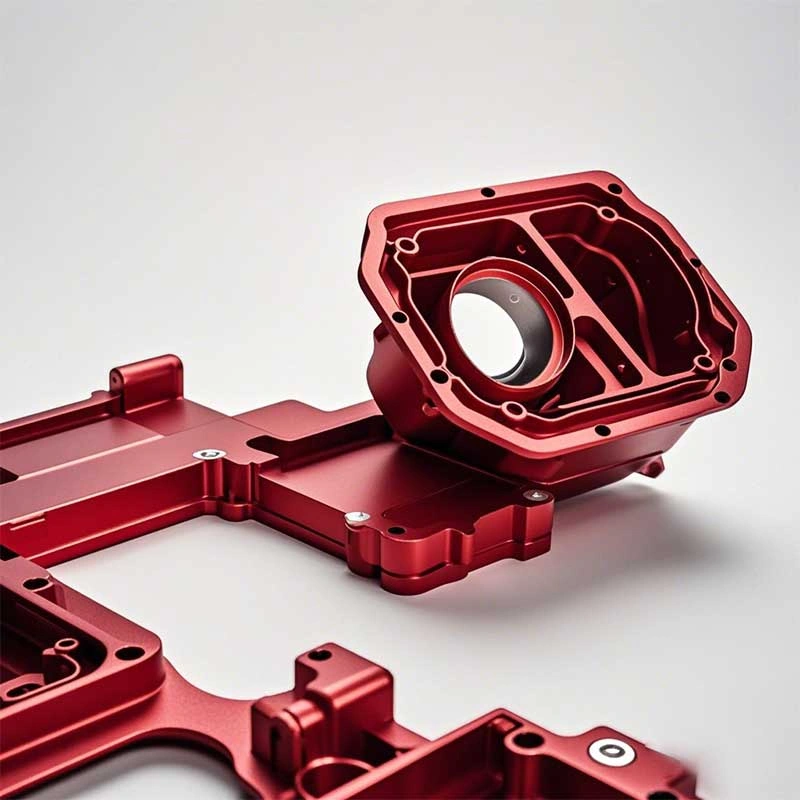

In our daily work, we often receive inquiries from some customers who require anodizing surface treatment for their aluminum die casting products. Since customers often see that the appearance of some anodized aluminum products is very nice and beautiful, they naturally assume that anodizing can also be done on aluminum alloy die-casting products. So, are aluminum alloy die-casting products suitable for anodizing?

|

|

|

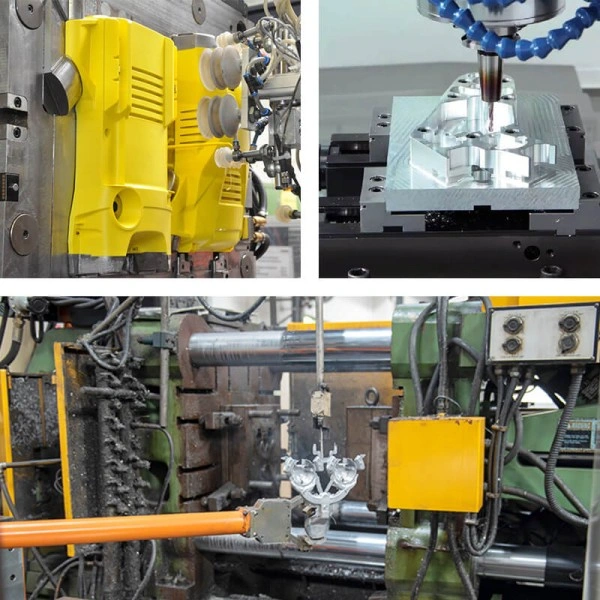

Problems Existing in Anodizing of Aluminum Alloy Die Castings

We hold the view that it is not advisable to apply anodizing surface treatment to aluminum alloy die-casting products. Instead, we suggest that alternative finishing processes such as passivation, painting, powder coating or electrophoresis can be carried out. For many die casting parts, these coatings ensure better adhesion, more consistent surface finish, and stable performance.

Because, in the aluminum alloy die-casting industry, ADC12 is a commonly used material in China at present. This material contains a relatively high amount of silicon. Since the shapes of die-casting products are various, silicon is added to improve the fluidity of the material; otherwise, it would be difficult to shape. During anodizing treatment, a layer of grayish-black powder is likely to appear on the surface of the die-castings, resulting in a blackish or grayish appearance, and even peeling may occur. The smoothness and aesthetics of the surface will be poor, which is generally unacceptable to customers and fails to meet the requirements of mass delivery. This can also be reasonably regarded as product defects, and the defect rate is relatively high, thus significantly increasing the production cost.

|

|

In addition, during the cooling and solidification process of aluminum alloy die-casting products, the surface is usually relatively rough and may have pores and blowholes. These tiny pores will hinder the formation of the oxide film and the uniformity of film formation. The existence of pores and blowholes will cause the anodized film to be not dense and complete enough, which will also affect its performance and appearance.

Conclusion

In conclusion, regarding whether aluminum alloy die-casting products are suitable for anodizing, our professional die casting services team recommends considering other finishing processes such as painting, powder coating, or electrophoresis for better results. We welcome discussions and exchanges to choose the most appropriate surface treatment for your project needs.