In real project communication, we often see customers specify a material grade at the very beginning. Still, in many cases, that material is not suitable for die casting. For example, last year we handled a new energy vehicle (NEV) structural part project in which the customer insisted on using 6061 aluminum alloy—we declined because it was not feasible. Another medical equipment customer wanted precision parts in 304 stainless steel. They originally planned CNC machining, then considered switching to die casting for mass production while still keeping 304. That is also not feasible.

1) Which Materials Are NOT Suitable for Die Casting? A Practical Pitfall-Avoidance Guide

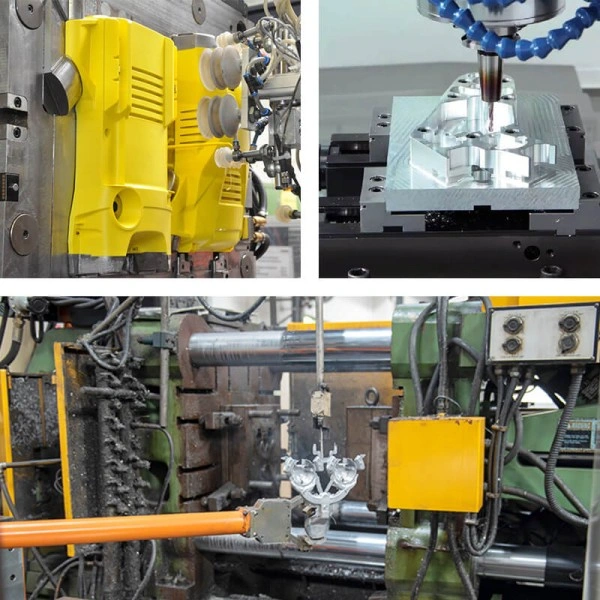

Die casting is essentially high-pressure, high-speed mold filling. The material’s fluidity, melting point, and shrinkage rate directly determine whether the process succeeds. Based on Shine-Choose Precision Intelligent Manufacturing’s experience, the following materials are almost impossible to die cast and should be ruled out in advance:

1. Wrought Aluminum Alloys: 6061, 6063, etc.

We have encountered these alloys many times in automotive structural part projects. They belong to “wrought processing alloys.” Their silicon content is usually below 1%. In the molten state, they behave like thick honey and cannot rapidly fill complex mold cavities under high pressure. If the customer needs a similar strength, we typically recommend switching to a die-casting-specific aluminum alloy, rather than forcing 6061 into die casting.

2. 300-Series Stainless Steels, Structural Steels such as Steel 25L

304 stainless steel has a melting point above 1400°C, while the temperature tolerance of our die casting molds is usually no more than 700°C. We once had a customer request die casting for a 316 stainless steel communication enclosure—completely unrealistic. Structural steels like Steel 25L are even more troublesome: the shrinkage rate can exceed 2%, and post-forming dimensional deviation can reach ±0.5 mm, which cannot meet precision-part requirements.

3. Silicon Bronze, High-Carbon Steel, and Other Special Alloys

Silicon bronze has a wide crystallization temperature range during die casting, making it impossible to pass airtightness (leak) tests. High-carbon steel oxidizes easily in the molten state; castings end up full of porosity. After polishing, pinholes are everywhere, and post-processing costs can exceed the casting cost.

2) Common Die Casting Materials and Key Characteristics: Choosing the Right Material Matters

Materials suitable for die casting must be “highly fluid, easy to form, and stable in shrinkage.”

Aluminum Alloys (Most Common)

| Grade | Melting Point (°C) | Fluidity (mm) | Shrinkage (%) | Key Features | Typical Applications |

|---|---|---|---|---|---|

| ADC12 | 580-620 | ≥350 | 1.0-1.2 | Excellent fluidity, easy to form | Complex structural parts (automotive motor covers, medical device handles) |

| A380 | 570-610 | ≥320 | 0.9-1.1 | High strength, strong load-bearing capability | Load-bearing components (NEV structural parts, industrial enclosures) |

| A356 | 610-650 | ≥280 | 1.0-1.3 | Corrosion resistant (after passivation, salt spray ≥96 h), density deviation ±0.01 | Outdoor equipment (communication enclosures, energy equipment housings) |

Zinc Alloys (Best Low-Cost Option)

| Grade | Melting Point (°C) | Fluidity (mm) | Shrinkage (%) | Key Features | Typical Applications |

|---|---|---|---|---|---|

| Zamak 3 | 380-390 | ≥400 | 0.5-0.7 | Well-balanced properties, great cost performance | Small-to-medium precision parts (mouse housings, camera frames) |

| Zamak 5 | 385-395 | ≥380 | 0.6-0.8 | ~20% higher strength than Zamak 3 | Structural parts (steering wheel frames, equipment handles) |

| ZA-8 | 400-410 | ≥350 | 0.7-0.9 | Good high-temperature stability (no deformation at -40 to 120°C) | High-temperature applications (lamp brackets, engine-adjacent components) |

Magnesium Alloys (Best for Lightweighting)

| Grade | Melting Point (°C) | Fluidity (mm) | Shrinkage (%) | Key Features | Typical Applications |

|---|---|---|---|---|---|

| AZ91D | 590-610 | ≥300 | 1.2-1.4 | Balanced strength and corrosion resistance (density 1.8 g/cm³) | Lightweight housings (laptop housings, defense equipment enclosures) |

| AM60B | 600-620 | ≥280 | 1.1-1.3 | High toughness, impact strength 120 MPa | Impact/load parts (automotive safety structures, special equipment frames) |

Copper Alloys (High Strength, High Wear Resistance)

| Grade | Melting Point (°C) | Fluidity (mm) | Shrinkage (%) | Key Features | Typical Applications |

|---|---|---|---|---|---|

| C36000 | 900-920 | ≥250 | 1.5-1.7 | Excellent machinability, conductivity ≥45% IACS | Precision conductive parts (connectors, heat dissipation components) |

| C83600 | 880-900 | ≥230 | 1.4-1.6 | Hardness HB ≥80, excellent wear resistance | Friction components such as bearings and gears |

3) If the Material Is Not Suitable: Alternative Solutions That Work

If your specified material is not suitable for die casting, we usually propose alternatives based on three criteria: “similar performance, feasible process, and controllable cost.” Below are two common cases:

Case 1: Originally Specified 6061 Aluminum Alloy (Needs Strength + Lower Cost)

6061 cannot be die cast. Depending on the project requirements, we may recommend:

- ADC13 aluminum alloy: Strength close to 6061 (tensile strength ≥220 MPa). Commonly used in our automotive aluminum housing projects, with stable yields above 95%.

- Zamak 5 zinc alloy: About 30% lower cost than aluminum, suitable for small-to-medium non-load-bearing parts. For example, we produced mouse housings at a monthly output of 100,000 pcs without issue.

- AZ91D magnesium alloy: If weight is critical (e.g., drone structural parts), density is only 1.8 g/cm³—about 30% lighter than aluminum. Our magnesium die-casting equipment can produce over 150,000 pieces per month.

Case 2: Originally Specified 304 Stainless Steel (Needs Corrosion Resistance + Precision)

Die casting 304 stainless steel is not realistic. Alternatives include:

- A356 aluminum alloy + passivation: Used for NEV charging station housings. After passivation, the neutral salt spray test can reach 96 hours (rating 10). Corrosion resistance can be close to stainless steel, while the cost drops by 50%.

- C83600 copper alloy: If wear resistance is required (e.g., gearbox components), hardness can exceed stainless steel. After die casting, CNC machining accuracy can reach ±0.02 mm.

Conclusion

There is no single “best” die casting material—only the “most suitable.” We once had an automotive motor cover project where the customer initially specified A380. After evaluation, we found the structure was simple and switched to ADC12, reducing the cost by 15% while fully meeting the performance requirements. Confirming material compatibility early can prevent many detours—after all, mold making takes about 30 days, and trial costs are not low. Before asking suppliers for quotations, it is recommended to understand die-casting materials first and verify whether they meet your project requirements.