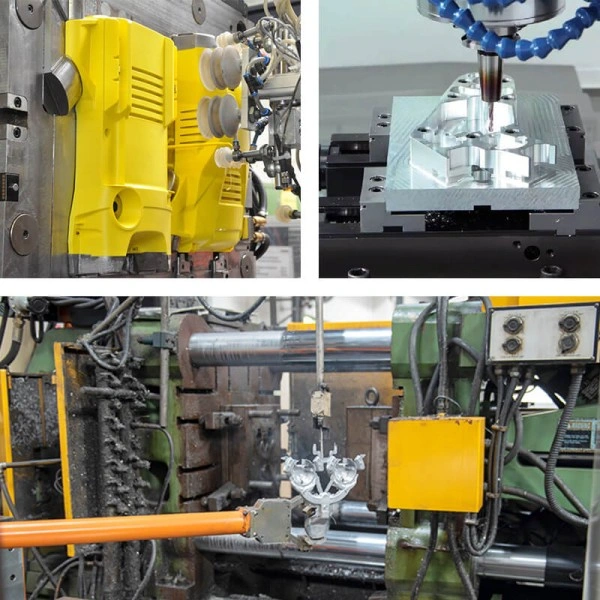

The performance and cost of a die-cast product depend on alloy selection. Aluminum, zinc, and magnesium alloys are the three primary die-casting materials, and their application scenarios vary significantly. This article organizes the selection logic and practical guidelines for purchasing, engineering, and quality teams, from the perspectives of material properties, process parameters, cost structure, and quality control.

1. Aluminum Alloy Die Casting: Excellent Cost-to-Performance, Balanced Performance & Manufacturability

Aluminum alloy is the most widely used material in die casting. The mainstream grades ADC12 (general-purpose) and A380 (high-strength) differ significantly in performance: ADC12 density 2.7g/cm³, melting point 660℃, suitable for medium-strength structural parts; A380 density 2.8g/cm³, with better heat resistance, suitable for high-temperature environments. Their key advantages are cost-effectiveness and process maturity.

1. Die Casting Characteristics & Advantages

- Clear performance segmentation: ADC12 tensile strength 160-200MPa, hardness HB 80-100, suitable for general structural parts; A380 tensile strength 230-270MPa, hardness HB 90-110, suitable for automotive powertrain loads.

- Process parameters are highly controllable: High-pressure die casting mold temperature 200-250℃, injection speed 3-5m/s, capable of 0.5-0.8mm thin walls (small parts down to 0.5mm); mold life 300,000-500,000 shots, suitable for mass production.

- Clear cost structure: ADC12 raw material approx. RMB 28,000/ton; mold cost amortization 1.5-3 RMB/pc at 100,000 pcs; anodizing increases cost 8%-12%. Overall, 30%-40% lower cost vs magnesium alloy.

- Limitations & solutions: Susceptible to shrinkage porosity (mainly due to wall thickness variation); by optimizing the gating system (e.g., adding overflow wells) + T6 heat treatment (530℃ solution + 160℃ aging), porosity can be controlled below 0.5%.

2. Suitable Product Types

- Automotive Powertrain: Transmission housings (A380 grade, “HPDC + T6 heat treatment”, specific pressure 60-80MPa, tensile strength ≥230MPa), motor end covers (ADC12, X-ray inspection ASTM E1417, porosity area ≤0.5%).

- 3C Electronics Structural Components: Laptop housings (ADC12, extrusion + CNC machining, anodizing thickness ≥8μm, per GB/T 8013), tablet mid-frames (A380, hardness HB≥90, improved anti-deformation).

- Industrial Equipment: Air conditioner compressor parts (ADC12, tensile test per GB/T 228, yield strength ≥110MPa), machine equipment frames (A380, good weldability, suitable for assembled structures).

3. Quality Control & Supplier Requirements

- Main inspection items: Tensile strength (GB/T 228, ADC12≥160MPa, A380≥230MPa), hardness (HB 80-110), dimensional tolerance (ISO 2768-m); salt spray test after surface treatment (NSS) ≥500h without white rust.

- Typical quality issues: Oxide film delamination (root cause: insufficient degreasing in pretreatment); prevention: extend alkali cleaning to 5-8 minutes, anodizing voltage 12-15V.

- Supplier qualification: Automotive requires IATF16949; capacity ≥500,000 pcs/year (for delivery stability).

2. Zinc Alloy Die Casting: Best Choice for Precision Small Parts, Outstanding Formability and Detail Reproduction

Zinc alloy mainly uses ZAMAK 3 (general-purpose) and ZAMAK 5 (high-strength): ZAMAK 3 density 6.5g/cm³, melting point 385℃, best fluidity; ZAMAK 5 adds copper, increases strength by 15%, suitable for slightly loaded functional parts. Their core advantages are precision and low cost.

1. Die Casting Characteristics & Advantages

- Significant performance differences: ZAMAK 3 tensile strength 280MPa, hardness HB 82-94, suitable for decorative parts; ZAMAK 5 tensile strength 320MPa, hardness HB 95-105, suitable for light-load functional parts.

- Optimized process parameters: Hot chamber die casting mold temperature 60-80℃, injection speed 1-3m/s, minimum wall thickness 0.4mm; mold life 500,000-800,000 shots, suitable for high-volume small parts (MOQ≥50,000 pcs).

- Clear cost advantages: ZAMAK 3 raw material approx. RMB 22,000/ton, scrap recycling rate 95% (offsets 10%-15% raw material cost). Unit price is 15%-20% lower than that of aluminum alloy small parts.

- Limitations & solutions: Prone to aging deformation (intergranular corrosion causes “zinc pest”), prevented by controlling impurities (automotive grade Pb≤0.004%, Cd≤0.003%, general parts meet RoHS 2.0) + 100℃×24h aging treatment.

2. Suitable Product Types

- Precision Electronics: Remote control keys (ZAMAK 3, hot chamber die casting, specific pressure 30-50MPa, Ra≤1.6μm), camera brackets (ZAMAK 5, dimensional tolerance ±0.05mm, CMM inspection required).

- Automotive Interior: Door handles (ZAMAK 3, phosphating before plating, multi-layer plating Cu-Ni-Cr required for ≥1000h salt spray), dashboard trim (ZAMAK 5, laser-engraved texture, depth tolerance ±0.02mm).

- Hardware Accessories: Zipper pullers (ZAMAK 3, multi-cavity mold, ≥500 pcs/hour productivity), lock components (ZAMAK 5, hardness HB≥95 for wear resistance).

3. Quality Control & Supplier Requirements

- Main inspection items: Tensile strength (GB/T 228, ZAMAK 3≥280MPa, ZAMAK 5≥320MPa), intergranular corrosion (ISO 4520 immersion test, no cracking), plating adhesion (cross-cut test GB/T 9286, grade 0 qualified).

- Typical quality issues: Plating blistering (root cause: casting surface porosity > φ0.1mm); prevention: increase injection speed to 2-3m/s, vent depth 0.15-0.2mm.

- Supplier qualification: General parts require ISO 9001; automotive interior requires IATF16949; capacity ≥1,000,000 pcs/year (to support hot chamber continuous production).

3. Magnesium Alloy Die Casting: Lightweight Champion, Irreplaceable in Extreme Weight Reduction

Magnesium alloys mainly use AZ91D (castable) and AM60 (high-ductility): AZ91D density 1.8g/cm³, specific strength 250MPa/(g/cm³), suitable for structural parts; AM60 has better toughness (elongation 8%-12%, semi-solid die casting up to 12%-15%), suitable for impact-resistant applications. Their core advantages are weight reduction and damping.

1. Die Casting Characteristics & Advantages

- Precise performance matching: AZ91D tensile strength 230-260MPa, hardness HB 65-80, suitable for static structural parts; AM60 tensile strength 260-290MPa, elongation 8%-12% (semi-solid 12%-15%), suitable for impact-loaded parts (e.g., steering wheel skeletons).

- Higher process threshold: Semi-solid die casting mold temperature 180-220℃, injection speed 4-6m/s, solid fraction 30%-60%, porosity ≤1%; molds require H13 hot work steel, life 200,000-300,000 shots.

- Special cost structure: AZ91D raw material approx. RMB 45,000/ton, molds 20%-30% more expensive than aluminum alloy, but weight reduction can offset >30% total cost (e.g., EV range +5%-8%).

- Limitations & solutions: Prone to corrosion (salt spray <24h in normal state). Micro-arc oxidation (thickness ≥ 15 μm) combined with an epoxy coating can achieve ≥1000 h of salt spray testing.

2. Suitable Product Types

- High-end 3C Devices: Professional camera chassis (AZ91D, semi-solid casting, porosity ≤0.5%, X-ray ASTM E1417), laptop C-shell (AM60, excellent damping, damping coefficient 0.015-0.02).

- Automotive Lightweight Components: EV battery pack brackets (AZ91D, “semi-solid + T4 heat treatment”, weight reduction >30%), steering wheel skeletons (AM60, elongation ≥10%, meets ISO 12405 impact).

- Aerospace: Drone fuselage (AZ91D, density 1.8g/cm³, specific strength 250MPa/(g/cm³)), satellite components (AM60, AS9100 required, dimensional stability ≤0.05mm/m).

3. Quality Control & Supplier Requirements

- Main inspection items: Tensile strength (GB/T 228, AZ91D≥230MPa, AM60≥260MPa), porosity (ASTM B94, ≤0.5%), stress corrosion (ISO 11433, 1000h without cracking).

- Typical quality issues: Stress corrosion cracking (root cause: residual stress >50MPa); prevention: 160℃×2h stress relief + FEA-based cooling system optimization.

- Supplier qualification: Automotive requires IATF16949; aerospace requires AS9100; semi-solid process capability required (e.g., Automotive SPICE Level 2).

4. Quick Selection Comparison Table: One-Page Overview of Alloy Application Scenarios

| Dimension | Aluminum Alloy Die Casting (ADC12/A380) | Zinc Alloy Die Casting (ZAMAK 3/5) | Magnesium Alloy Die Casting (AZ91D/AM60) |

|---|---|---|---|

| Density | 2.7-2.8g/cm³ | 6.5-6.7g/cm³ | 1.7-1.9g/cm³ |

| Die Casting Temperature Range | Mold 200-250℃, Melt 650-680℃ | Mold 60-80℃, Melt 380-400℃ | Mold 180-220℃, Melt 680-720℃ |

| Minimum Wall Thickness | 0.5-0.8mm (down to 0.5mm) | 0.4mm (hot chamber) | 0.5mm (semi-solid) |

| Mold Life | 300,000-500,000 shots | 500,000-800,000 shots | 200,000-300,000 shots (H13 tool steel) |

| Common Defects | Shrinkage porosity, oxide inclusions | Gas porosity, flow marks | Oxidation burn, stress cracking |

| Typical Products | Transmission housings, laptop housings | Electronic keys, automotive interior trim | Camera chassis, automotive lightweight structures |

| Core Advantage | High cost-performance, mature process, balanced strength | Precision detail, fine features, lower cost | Extreme lightweight (30% lighter than aluminum), damping |

| Cost (RMB/pc, 100k batch) | 5-15 (incl. anodizing) | 1-8 (incl. plating) | 15-40 (incl. micro-arc oxidation) |

5. Selection Summary: Start from Actual Requirements, Match the Best Alloy

- If cost-performance and general use are key: choose aluminum alloy (ADC12/A380), suitable for powertrain and appliance structures, focus on supplier IATF16949 and mold amortization (100k pcs batch optimal).

- If precision small parts and fine detail are key: choose zinc alloy (ZAMAK 3/5), suitable for electronic keys and decorative parts, prioritize hot chamber suppliers (≥1,000,000 pcs/year), control phosphating quality before plating.

- If extreme lightweight is required: choose magnesium alloy (AZ91D/AM60), suitable for high-end 3C and automotive lightweight components. Suppliers must have semi-solid die-casting capability (AS9100/IATF16949), with emphasis on stress-relief process control.

Engineering, purchasing, and quality teams can combine weight (magnesium 30%+ lighter), structural complexity (zinc 0.4mm thin walls), and budget (aluminum 5-15 RMB/pc) to quickly lock the right solution. For further evaluation, please provide drawings (including load analysis) and batch demand to obtain a customized die-casting solution.