Sourcing die casting molds is often a “high-risk zone” for buyers: molds that are advertised with a lifetime of 500,000 shots may show severe cavity wear after only 120,000 shots in actual production (actual mold life depends on steel grade, heat treatment, process control and maintenance; any single case is not universally representative and must be verified against real inspection reports). Quotations that look “budget-friendly” at the beginning later balloon by 30% under pretexts such as “material upgrade” or “process adjustment” (any price adjustment ratio must follow the contract and the actual scope of changes). Suppose there is no cap on trial runs and design changes. In that case, additional rework costs can easily exceed RMB 80,000 (modification costs should be clearly defined in the contract based on the actual scope of modification, e.g., structural changes, accuracy adjustments, etc.). These problems not only drive production costs through the roof but can also bring the entire production line to a halt. As some long-term customers bluntly put it: “Overstated mold life forces us to replace tools in half a year, costing us millions”, “The quotation is just ‘bait’—we ended up paying more in surcharges than for the mold itself”, “No upper limit on trial and rework fees; we were literally ‘milked’ by the supplier.” Based on real lessons from dozens of companies, this article distills four key points to avoid these traps. Each point directly affects cost and delivery, and every line should be checked carefully.

Beware of Overstated Tool Life: The Reality of Durability in a “High-Pressure” Die Casting Environment

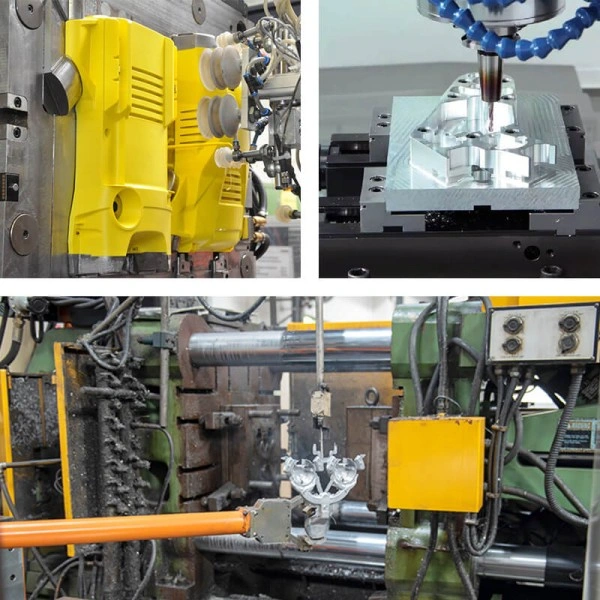

Mold life is a core purchasing metric, but the “high-pressure nature” of die-casting molds makes misrepresentation of mold life far more common than with other types of tooling. Die casting molds typically operate under impact pressures ranging from several tens to over 100 megapascals. In contrast, the injection pressure for plastic molds is often only one-fifth to one-third that of metal molds. If the mold steel is substandard or heat treatment is inadequate, early failure is highly likely. One customer, for example, reported: “We bought a die casting mold that promised a life of 500,000 shots, but severe cavity wear appeared after only 120,000 shots, whereas an injection mold purchased at the same time still ran well after 300,000 shots under similar conditions.” (Actual mold life—whether die casting or injection—depends on steel grade, heat treatment, process, and maintenance; individual cases are not representative of the general level and must be supported by real testing and inspection reports.) Key actions to avoid this trap:

- Require the supplier to provide material certificates (e.g., mold steel grade and composition test reports) and heat treatment records (hardness values, number of tempering cycles), and reject purely verbal assurances.

- Insist on life test data (for example, cavity wear measurements after a simulated 10,000-shot test), and clearly define “life-based compensation” in the contract (by referring to lifetime guarantee clauses in standard industry procurement contract templates). For instance: “For every 10% that actual mold life falls short of the guaranteed value, 15% of the mold payment shall be deducted.”

Avoid Quotation Traps: Low Prices Are Often “Bait” — Use Transparent Cost Breakdown + Standard Contracts as Double Insurance

For die casting mold quotations, “vague pricing” is the most enormous red flag, especially when it comes to abnormally low prices used as a lead-in. Less professional suppliers often reuse generic quotation templates and only show a “base price” at first; once the order is secured and the real cost overruns appear, they then request additional charges for items such as “material upgrades” or “process changes”. One client shared: “We once accepted a mold quoted at RMB 200,000. Later the supplier claimed they needed to ‘thicken the plates due to high die casting pressure’ and ‘apply hard chrome plating to the cavity’, and we ultimately paid RMB 260,000.” (Any additional charges must be governed by the contract and by the actual scope of technical changes.)

Why is an abnormally low price almost always a trap? Die casting molds require high-grade steels such as H13 or 1.2344/8407 and must undergo multiple heat-treatment steps, including quenching and tempering (with a typical cavity hardness of HRC 48–52). Material and machining costs are inherently higher than for plastic injection molds. If a quotation is more than 30% below the prevailing market level for comparable molds (for example, when similar tools are generally quoted at RMB 300,000 but a supplier quotes RMB 200,000), the cost structure and process completeness must be carefully reviewed. There is a high risk of corner-cutting, such as using inferior steel or omitting proper heat treatment.

- Demand a fully itemized quotation that clearly lists: mold steel grade and purchase price (with supplier invoices attached), machining operations (CNC machining hours, number of EDM operations), heat treatment processes (quenching temperature, number of tempering cycles), etc. A definable basis should back each cost item.

- Sign a fixed-total-price contract that specifies “Other than items explicitly stated in the contract, any additional cost shall be borne by the supplier”, and reference fixed-price clauses from standard industry purchasing contract templates to lock in costs from a legal perspective.

“Lock In” Trial & Modification Costs: Cap Both Times and Amounts to Avoid a Bottomless Pit

Trial runs and mold modifications are the final gate before mold acceptance, but without clear limits, they can become a major money sink. One customer shared a painful lesson: “Our contract just said ‘trial and modification fees included’ with no mention of limits. After five trials and three rounds of modification, the supplier claimed that any trial beyond the third would be charged extra. We ended up paying an additional RMB 80,000 just in modification fees.” (Modification charges must be clearly defined in the contract based on the actual scope of modification, such as structural changes or accuracy adjustments.)

- The contract must specify both upper limits: the number of free trials (for example, “Up to 3 trial runs free of charge; each additional trial run will be charged at RMB XX per time”) and the cap on modification costs (for example, “Total modification cost shall not exceed 10% of the mold contract price”). It should also state that “Any modifications resulting from supplier’s design errors or machining defects shall not count towards the specified limits in either trial times or modification costs.”

- With reference to trial and acceptance clauses in standard industry procurement contracts, define that “If the mold fails acceptance, the supplier must complete rectification within X days; for every day of delay, X% of the mold payment will be deducted”, thus putting real pressure on the supplier to get the design right in the early stages.

Supplier Selection Is Not Only About Price: Use Equipment Capability + Proven Case Studies as Hard Filters

“Cheap molds are bad molds” is a widely shared conclusion among experienced buyers. When selecting suppliers, you must avoid the “pure price comparison” trap and instead focus on two hard indicators:

- Processing equipment accuracy and configuration. Die casting mold cavity tolerances typically need to be controlled within 0.02 mm, which depends heavily on high-precision equipment. Require the supplier to provide a complete equipment list and pay special attention to: high-precision machining centers (e.g., DMG MORI DMC series, FANUC α-D series), EDM machines (sinker EDM such as Makino EDGE series), and WEDM machines (wire EDM such as Sodick AQ series), including model numbers and years in service (prefer suppliers with equipment less than three years old). Over-aged machines (in service for more than five years) are much more likely to cause dimensional deviation and unstable accuracy.

- Real data from same-industry reference projects. Do not accept “verbal reference cases”. Require documented die casting mold projects put into production within the last two years, including customer names (which can be cross-checked), mold steel specifications (with test reports), and actual production count (for example: “For a certain automotive die casting mold, after 18 months in production it ran 350,000 shots with cavity wear less than 0.03 mm”—this must be supported by material certificates and periodic wear inspection records for that specific mold). Where possible, conduct an on-site visit to the customer’s plant to verify the actual condition of the molds in operation.

Conclusion

When purchasing die casting molds, buyers must guard against four “life-or-death” lines: for tool life claims, verify steel grade and heat treatment and lock down warranty terms in the contract (with reference to standard industry clauses); for quotation traps, insist on a transparent cost breakdown and a fixed-price contract (and scrutinize any offer that is more than 30% below market level for comparable molds for potential process or material compromises); for trial and modification costs, define both the number of free trials and the cap on modification fees (and write both upper limits into the contract); and for supplier selection, evaluate equipment (models and years in service) and verify reference cases (time in production and actual achieved life). Only by embedding these checkpoints into the entire procurement process can you avoid “bait-and-switch” quality and out-of-control costs, and ultimately secure die casting molds that are truly durable, low-risk, and cost-effective.