Basic concepts of the die casting mold

The definition and working principle of the die casting mold

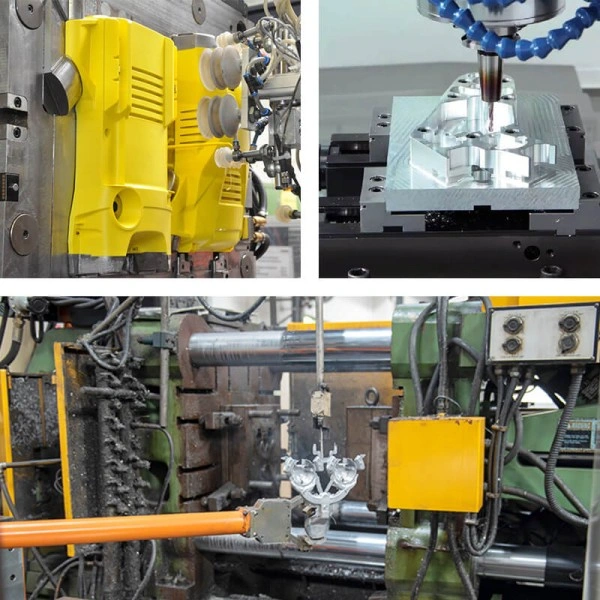

A die casting mold is a tool used to inject liquid metal or alloy into a mold cavity under high pressure to solidify and form the desired part or product. The die-casting mold consists of an upper mold and a lower mold. After the metal is injected, the mold cavity is filled with high pressure. After cooling, the mold is opened to take out the finished product.

The working principle of the die casting mold is mainly divided into the following steps:

- Mold closing: the upper and lower molds are closed to form a closed mold cavity.

- Injection metal: A nozzle injects liquid or alloy into the mold cavity.

- Filling the mold cavity: The metal fills the entire mold cavity under high pressure.

- Cooling and solidification: The metal gradually solidifies into shape.

- Open the mold and remove the parts: After the metal is completely solidified, the mold is opened, and the finished parts are removed.

Through this series of steps, die-casting molds can efficiently manufacture complex-shaped metal parts. They are widely used in automobile manufacturing, aerospace, electronic equipment, electrical appliances, instrumentation, consumer electronics, and other industries.

The role of die-casting molds in product production

- Manufacturing of products with complex shapes: Die-casting molds can be used to manufacture metal parts and products with complex shapes.

- Efficient production: Through die-casting molds, large quantities of finished products can be produced in a shorter time and at a faster speed.

- Improve product quality: Die-casting molds can ensure product consistency and precision, and produce products with accurate dimensions and reliable quality.

- Cost saving: Die-casting molds can save raw materials, workforce, and production cycles, and reduce product production costs.

Basic steps for making die casting molds

Before designing a custom die casting mold, you must first obtain the 3D drawings or physical samples of the product provided by the customer, and then design and manufacture the mold. The following are the brief steps for die-casting mold manufacturing:

- Confirm demand: Understand customer requirements and specifications for products.

- Analysis and design: Develop mold design based on physical samples or 3D drawings, considering the production requirements of multiple products within a single mold.

- Technical evaluation: Evaluate the design plan to ensure the mold structure is reasonable and meets production needs.

- Numerical simulation: Analyze the mold design plan through numerical simulation to verify its feasibility.

- Customer confirmation: Confirm the design plan with the customer, making modifications and optimizations until both parties reach a mutual agreement.

- Mold steel material selection: Select a suitable mold steel material, considering both service life and production efficiency.

- Mold design: Develop detailed mold design drawings and consider the design of multiple cavities in one mold and the feed port design.

- Manufacturing and processing: According to the mold design drawings, the mold parts are processed by turning, milling, boring, grinding, and other processing techniques to produce the upper mold, lower mold, slider, and other mold parts.

- Assembly and debugging: Assemble the mold parts, conduct opening and closing tests, de-molding tests, and debugging.

- Product trial production: Use molds to conduct product trial production and check product quality and molding conditions.

- Inspection and acceptance: Conduct a comprehensive inspection and approval of molds to ensure adherence to quality standards.

Such a process ensures the smooth progress of mold design and production.

Die casting mold material selection

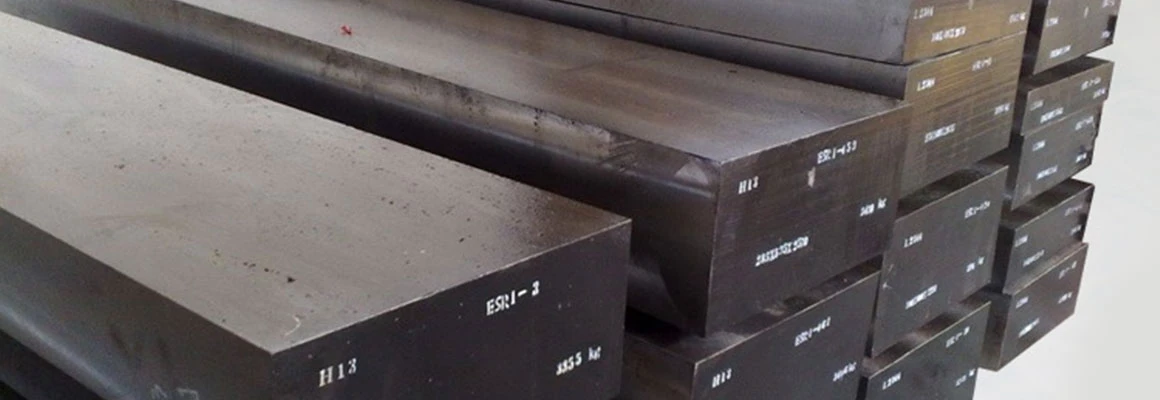

When selecting steel for use in making die casting molds, some of the following factors are considered:

- Heat resistance: The die-casting process needs to withstand high temperatures and pressure, so steel with good heat resistance needs to be selected, such as H13 and H11 steel.

H13 steel exhibits good wear and thermal shock resistance, making it suitable for prolonged use at high temperatures.

H11 steel has high thermal strength and good thermal shock stability, and it is suitable for manufacturing large molds or high-pressure molds.

- Wear resistance: Molds will frequently come into contact with liquid metal during production, so steel materials that can withstand the impact and friction of high-speed liquid metal are required, such as 718 steel.