1. Why Is Die Casting Machine Tonnage the “First Gate” in Production?

Aluminum alloy die castings, thanks to their lightweight (about 30–40% lighter than steel), high strength (tensile strength ≥ 250 MPa), and high dimensional accuracy (tolerance up to ±0.1 mm), have become core components in the automotive, 3C electronics, and new energy industries.

The tonnage of a die casting machine (clamping force, in tons) directly determines whether your parts can be produced stably and consistently:

If the tonnage is too small

- Insufficient clamping force → parting line opens during shot

- Results: molten aluminum flash, heavy burrs, unstable parting line, dimensional issues

If the tonnage is too large

- Higher equipment investment (oversized machines can cost 30–50% more than an appropriately sized model)

- Higher energy consumption (idle / no-load power consumption can increase by 40%+)

- Higher mold wear (mold life may drop by 20–30%)

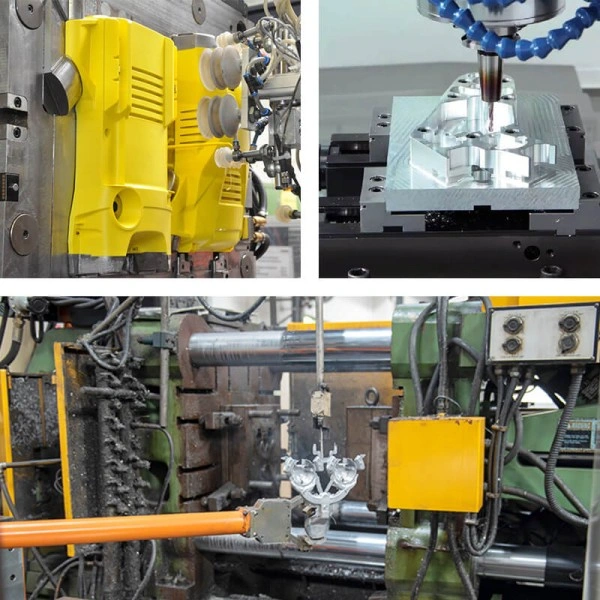

Shine-Choose operates a full range of horizontal cold-chamber aluminum die casting machines: 280T, 300T, 400T, 420T, 580T, 900T, 1250T, covering part weights from a few grams to dozens of kilograms.

This guide will help you quickly match “part type ↔ machine tonnage”, avoid selection pitfalls, and reduce trial-and-error cost.

2. Shine-Choose Machine Tonnage Range: From Small Precision Parts to Heavy Structural Castings

(1) Small Precision Parts – 280T / 300T

The “precision partner” for 3C electronics and small automotive components

Clamping force: 2800 kN / 3000 kN

(Rule of thumb: 1 ton ≈ 10 kN → 280T ≈ 2800 kN)

Key strengths:

- High-pressure, low-speed filling

- Excellent for thin-wall precision parts

- Dimensional tolerance can be controlled within ±0.1 mm

Typical applications:

- 3C electronics

- Connectors, sensor housings (wall thickness 1–2 mm)

- Smartphone frames (shot weight 0.2–0.5 kg)

- Automotive electronics

- Door handles, mirror brackets (0.3–0.8 kg, wall thickness 1.5–3 mm)

- Smart home devices

- Miniature motor housings, smartwatch brackets

- Complex geometries suitable for multi-cavity molds

Typical customer case:

- A 3C supplier uses a 280T machine to produce a 0.4 kg sensor housing.

- Single-shift output: approx. 4000 pcs

- Stable yield: ≥ 98%

(2) Medium-Sized General Parts – 400T / 420T

The “volume workhorse” for automotive and home appliance parts

Clamping force: 4000 kN / 4200 kN

Key strengths:

- Balanced precision + productivity

- Typical single-shift output: 3000–5000 pcs

- Ideal for medium batch production

Typical applications:

- New energy vehicles (NEV)

- Motor end covers (1.5–3 kg, wall thickness 2–4 mm)

- Battery pack brackets

- Home appliances

- Air-conditioning compressor components (2–4 kg, wall thickness 3–5 mm)

- Washing machine clutch housings

- Motorcycle industry

- Engine housings (3–5 kg, medium structural complexity)

Tonnage selection tip:

For parts with 1–5 kg shot weight and 2–5 mm wall thickness, 400T / 420T typically offers the best cost-to-performance ratio.

(3) Large Structural Parts – 580T

A reliable choice for automotive powertrain components

Clamping force: 5800 kN

Key strengths:

- Strong feeding and shrinkage compensation capability under high pressure

- Can handle localized thick-wall areas (thick sections ≤ 30% of the overall structure)

- Helps eliminate porosity and shrinkage defects

- Able to meet air-tightness requirements (e.g., leak rate ≤ 10 cc/min)

Typical applications:

- Automotive

- Transmission housings (5–10 kg, wall thickness 4–8 mm)

- Steering knuckles

- New energy

- Small battery trays (8–12 kg, wall thickness 5–7 mm)

- Industrial machinery

- Hydraulic valve bodies, motor brackets

- Load-bearing parts with tensile strength ≥ 200 MPa

Attention point:

For thick-wall parts (> 5 mm), it’s recommended to use 580T or above to reduce the risk of shrink porosity and internal shrinkage cavities.

(4) Heavy Integrated Castings – 900T / 1250T

The “backbone tonnage” for new energy and heavy industry structural parts

Clamping force: 9000 kN / 12500 kN

Key strengths:

- Very high clamping force for large projected area castings

- Suitable for deep cavities (≥ 100 mm) and overall thick-wall designs (5–12 mm)

- Meets demanding high-strength (≥ 250 MPa) and fatigue-resistance requirements

Typical applications:

- New energy vehicles

- Chassis structural components (15–30 kg, wall thickness 8–12 mm)

- Large battery trays / battery pack housings

- Commercial vehicles

- Engine blocks (20–40 kg, multiple complex internal cavities)

- Heavy industry

- Large machine tool beds

- Structural brackets for construction machinery

- Require impact resistance and fatigue life ≥ 10⁵ cycles

3. 3-Step Quick Tonnage Selection – Decide Within 1 Minute

Step 1 – Pre-selection by Part Weight (Key reference)

| Single-part weight | Recommended machine tonnage | Typical parts |

|---|---|---|

| < 1 kg | 280T / 300T | Smartphone frames, sensor housings |

| 1 – 5 kg | 400T / 420T | Motor end covers, compressor components |

| 5 – 15 kg | 580T | Transmission housings, small battery trays |

| > 15 kg | 900T / 1250T | Chassis parts, engine blocks |

Step 2 – Adjust by Wall Thickness & Geometry

Thin-wall precision parts (< 3 mm)

Even if the shot weight is close to 1 kg, a 280T / 300T is often preferred.

Example: a 0.8 kg 4C connector with a 1.2 mm wall thickness is more suitable for a higher-precision machine such as 280T / 300T.

Thick-wall / deep cavity parts (> 5 mm or cavity depth ≥ 100 mm)

Even if the weight “fits” a smaller machine, it’s necessary to upsize the tonnage.

Example: an 8 kg transmission housing with 6 mm wall thickness should run on 580T, not 420T.

Highly complex parts (multi-cavity + deep cores)

It’s recommended to add a 10–20% safety margin to the clamping force to avoid issues such as incomplete fill, short shots, or severe porosity.

Step 3 – Benchmark Against Industry Cases

If you’re new to aluminum die casting, you can reference similar parts in your industry:

- Automotive motor end covers (around 3 kg) → usually 400T

- Smartphone frames (around 0.3 kg) → almost all use 280T

This helps you avoid “blindly going bigger” on tonnage.

4. Real-World Cases: The Cost of Choosing the Wrong Tonnage

Case 1 – “Small” machine forced to run a “big” product → Yield drops to 65%

A specific automotive supplier used a 300T die-casting machine to produce an 8 kg transmission housing with a 6 mm wall thickness.

Problems observed:

- Severe flash at the parting line

- Internal shrinkage and porosity (X-ray yield only 65%)

Root cause:

The 300T (3000 kN) machine did not provide enough clamping force to resist the cavity pressure and metal expansion force during high-pressure injection, resulting in parting-line opening and severe internal defects.

Case 2 – Oversized tonnage “killing a chicken with a bull knife” → Cost up by 40%

An electronics manufacturer used a 900T machine to produce a 0.3 kg smartphone frame (1.5 mm wall thickness). Although parts could be produced:

- Mold wear accelerated, mold life dropped from 100,000 shots → 60,000 shots

- Energy consumption increased by ~40% compared to a 280T machine

- Single-shift operating cost increased by about 3,500 RMB

This is a classic case of excessive tonnage leading to unnecessary costs.

5. Shine-Choose Tonnage Selection Support: “Get It Right the First Time”

If you’re still not sure which tonnage your product needs, Shine-Choose can provide free tonnage selection support:

Provide 3D part data

- Our engineering team can deliver a clamping force calculation report within about 3 hours, based on the projected area and required casting pressure.

Check mold-machine compatibility

- Verify whether your mold fits the machine tie-bar spacing.

- Example: a 580T machine with a 680 × 680 mm tie-bar spacing — we ensure your mold can be mounted without interference.

Trial production support

- Small batch trial runs: typically 100–500 pcs

- Validate machine stability, process window, and casting yield before mass production.

6. Conclusion

Tonnage selection for aluminum die casting machines is essentially about precisely matching “part requirements” with “equipment capability.”

With its 280T–1250T full range of cold-chamber die-casting machines, Shine-Choose can cover production needs from small 3C components to large new-energy structural castings.

By following the 3-step selection method:

- Weight-based pre-selection

- Adjustment by wall thickness and geometry

- Benchmarking against industry cases

You can avoid around 90% of common tonnage selection mistakes.

For projects converting from plastic parts to aluminum die castings, choosing the right tonnage typically means:

- Up to 30% reduction in equipment investment

- Around a 20% increase in production efficiency

- Up to 50% fewer quality issues

You can work with an aluminum die casting supplier like Shine-Choose that has years of die casting experience and let a professional engineering team help you match the most suitable die casting machine, so that you’re always using “the right machine for the right part.”