In the vast expanse of modern manufacturing, die casting, plastic injection molding, and machining shine brightly like dazzling stars, each emitting its unique brilliance and collectively contributing to the grand tapestry of industrial production. Now, let us delve deeper into the remarkable advantages that die casting offers compared to plastic injection molding and machining to assist you in making informed decisions about material and process selection during product development.

Comparison of Processing Techniques

1. Principle of the Die Casting Process

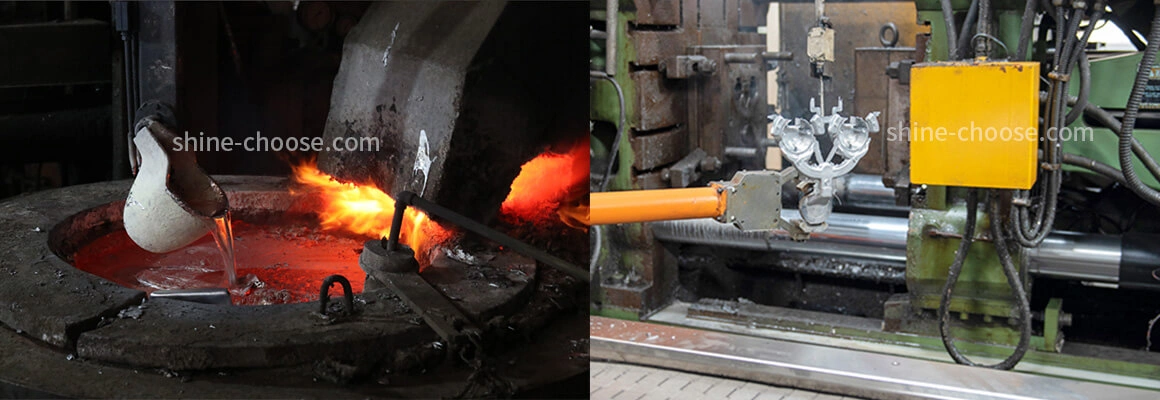

The die casting process involves injecting molten metal into a mold cavity under high pressure and speed, causing it to solidify rapidly into the desired shape. In this process, precise pressure control and superior mold design are crucial factors in ensuring the quality of the final product.

2. Principle of Plastic Molding Process

Injection molding involves heating plastic granules to a molten state and injecting them into a mold cavity under specific pressure and speed conditions. The plastic cools and solidifies, resulting in a plastic product. The core of this process lies in the careful selection of plastic materials and the precise setting of injection parameters.

3. Common Methods of Machining

Machining is a process that employs mechanical methods such as cutting, grinding, drilling, and others to progressively remove material from a workpiece to achieve the desired shape, size, and surface finish. This process requires high precision from the machine tools, careful selection of cutting tools, and meticulous planning of machining paths.

Comparison of Production Efficiency

1. Production Speed and Mass Production Capability of Die Casting

In practical manufacturing, die casting boasts high production speeds. For instance, in the production of automobile engine blocks, an average output of approximately two pieces per minute can be achieved. The output can reach 3 to 4 pieces per minute for aluminum alloy housings with simpler structures. Data from multiple die-casting enterprises indicate that the effective operating rate of equipment during mass production often exceeds 85%.

2. Efficiency Characteristics of Plastic Molding

Multiple factors influence the efficiency of plastic molding. For injection-molded parts of similar size and complexity to automotive engine blocks, the mold cycle takes 2 to 3 minutes. The actual time can vary significantly depending on mold quality, injection molding machine performance, etc.

3. Efficiency Limitations of Machining

Tool changes and process complexity constrain machining efficiency. Complex-shaped parts may take several days or weeks to produce in industries such as aerospace.

Cost Comparison

1. Cost Components of Die Casting

The cost of aluminum die casting comprises mold, material, energy, labor, and wastage. Mold cost is significant, energy consumption is high, and material wastage is about 3% to 5%.

2. Cost Components of Plastic Molding

The cost structure includes raw materials, energy, labor, and wastage. Material prices fluctuate greatly, energy consumption is relatively lower, and wastage is about 5% to 8%.

3. Cost Components of Machining

Machining costs include cutting tools, fixtures, energy, labor, and wastage. Tool replacements are frequent, wastage can reach 10% to 20%, and labor demand is higher.

Comparison of Precision and Quality

1. Precision and Quality of Die-casting Products

For automotive cylinder heads, die-casting achieves ±0.05mm dimensional precision, Ra0.8μm surface roughness, and high-quality die casting parts.

2. Precision and Quality of Plastic Products

Plastic products struggle to exceed ±0.2mm in dimensional precision due to shrinkage, with surfaces prone to wear.

3. Precision and Quality of Machining

Machining can achieve roundness within 0.005mm and Ra0.2μm surface finish but at high cost and low efficiency.

Comparison of Manufacturing Capabilities for Complex Shapes

1. Advantages of Die-casting

Die-casting efficiently produces complex parts such as transmission housings with oil passages, water channels, and multiple mounting holes in a single molding process.

2. Adaptability of Plastic Molding

Plastic molding can produce thin-walled electronic housings with good aesthetics but limited durability in high-stress environments.

3. Challenges of Machining

Machining complex geometries requires multiple setups and tool changes, leading to inefficiencies and higher costs.

Material Selection Comparison

1. Properties of Die-casting Materials

Common materials include aluminum, zinc, and magnesium alloys, suitable for automotive, aerospace, and electronics.

2. Types of Plastic Materials

Plastic materials are categorized as engineering plastics and commodity plastics. Engineering plastics like polycarbonate and nylon are durable, while commodity plastics like polyethylene and polypropylene are cost-effective.

3. Materials for Machining

Machining covers metals such as steel, copper, titanium alloys, ceramics, and composites.

Comparison of Operating Environments and Durability

1. Die-casting

Die-cast products offer excellent durability in high-temperature, humid, and corrosive environments with proper surface treatments.

2. Plastic Products

Plastics are vulnerable to UV, aging, and chemical exposure, limiting their long-term durability.

3. Machining

Machined parts are reliable in normal environments but may fail under extreme heat or corrosion without protection.

Conclusion

The die-casting process stands out in manufacturing for efficient speed, precision, cost-effectiveness, and ability to produce complex parts. Compared to plastic molding and machining, die-casting excels in high-volume, durable metal components with intricate structures and demanding environments.