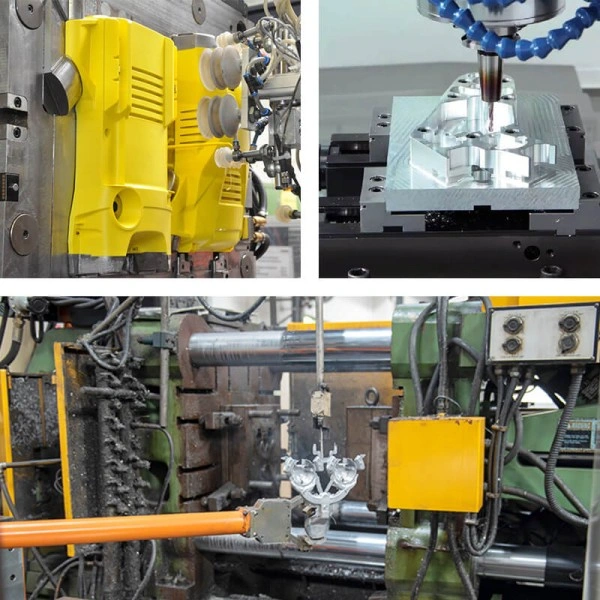

With the progress of society, many products are now developing towards lightweight. For example, some everyday 3C products have gradually been produced with magnesium alloy materials, thus getting rid of the drawbacks of being bulky and inconvenient in the past. Most of the magnesium alloy products on the market have achieved mass production through the process of magnesium alloy die casting. Today, let’s talk about what surface treatment processes are suitable for magnesium alloy die castings.

I. Passivation Treatment

Passivation treatment is a widespread surface treatment process for magnesium alloy die castings. It mainly forms a dense passivation film on the surface of the casting, improving its corrosion resistance and wear resistance. It can also enhance adhesion for additional treatments such as powder spraying or oil spraying. For products with low appearance requirements, passivation treatment is a basic yet effective method.

II. Powder Spraying Treatment

Powder spraying treatment evenly sprays powder coatings on the surface of the magnesium alloy die casting, then forms a coating through heating and curing. This coating effectively isolates the magnesium alloy from the external environment, providing corrosion resistance, wear resistance, and decorativeness. Moreover, powder spraying offers a variety of colors and textures, allowing customization of appearance and performance to meet specific product requirements.

III. Oil Spraying Treatment

Oil spraying treatment forms a protective film by spraying liquid paint on the surface of the magnesium alloy die casting and then drying and curing it. Oil spraying can also be blended to produce a range of colors and gloss levels, meeting diverse design requirements. For example, on magnesium alloy housings of 3C products such as laptops and smartphones, oil spraying can create fashionable appearances while protecting the internal structure from external damage, thereby extending product service life.

IV. Micro-arc Oxidation Treatment

Micro-arc oxidation treatment is a surface treatment technology developed from anodic oxidation. It uses high voltage to generate micro-arc discharges on the magnesium alloy surface, allowing the oxide film to grow and densify under high temperatures and pressures. The thickness can reach tens to hundreds of micrometers, with high hardness, wear resistance, and corrosion resistance. For example, magnesium alloy components in aerospace can withstand high-speed airflow and complex environmental erosion after this treatment.

V. Electroplating Treatment

Electroplating treatment includes nickel plating and chromium plating. Nickel plating forms a nickel layer with good corrosion resistance and decorative properties, giving the surface a bright metallic texture. Chromium plating forms a chromium layer with high hardness, wear resistance, and excellent reflectivity, making the surface even brighter and more durable.

Conclusion

These are some standard surface treatment processes for magnesium alloy die castings. Different products can choose different processes according to their specific requirements to achieve the desired appearance and performance. Shine-Choose provides professional die casting surface treatment solutions for both aluminum alloy and magnesium alloy products.