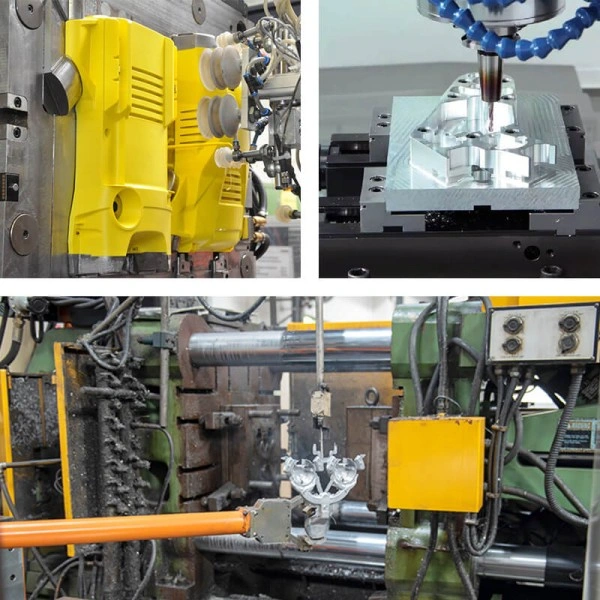

In our daily lives, I believe everyone is no stranger to aluminum alloy products. From small perfume aluminum caps to the frames and shells of some products, and even to some chassis accessories of new energy vehicles, etc., aluminum alloys are all applied in these. Most of these product accessories are produced through the die casting process. Do you know what surface treatments are done on these die-cast aluminum product accessories?

I. Grinding and Polishing

Applicable Scenarios:

1. Products with high appearance requirements that pursue a smooth and shiny surface texture, such as high-end exterior parts.

2. Accessories that need to reduce the surface roughness and have high requirements for surface flatness, such as some precision components.

|

|

Advantages:

1. After grinding and polishing, the surface finish of the product can be improved, making the product appearance highly glossy and shiny, enhancing the appearance of the product.

2. It can improve the flatness of the product surface, reduce surface defects, and improve the dimensional accuracy of the product, thereby enhancing the quality and performance of the product.

Disadvantages:

1. The cost is relatively high. Especially for some die-castings with special shapes, the difficulty of grinding and polishing will be relatively large, and the labor cost and time cost will also increase accordingly.

2. Generally, grinding and polishing will remove some materials. For accessories with high requirements for dimensional tolerances, the polishing allowance needs to be precisely controlled. Otherwise, it may affect the assembly accuracy of the accessories.

3. Although the surface is smooth after grinding and polishing, it may still be oxidized at room temperature. Therefore, additional surface treatments such as passivation, electrophoretic coating, powder spraying or oil spraying are often required.

II. Passivation and Whitening

Applicable Scenarios:

1. Suitable for die-cast aluminum accessories that need to improve corrosion resistance, especially products used in humid or corrosive environments, such as automobile spare parts and outdoor product shells.

2. More suitable for parts with a requirement for a silvery-white surface color and a certain metallic texture.

3. Applicable to products that need to enhance adhesion. The passivation film can provide a good adhesion foundation for subsequent surface treatments such as spraying and printing, making the coating more firm and durable.

| Before passivation | After passivation |

|---|---|

|

|

Advantages:

1. Improves the corrosion resistance of die-cast aluminum products by forming a passivation film on the surface to prevent oxidation and corrosion.

2. Produces a uniform silvery-white appearance, making the product look simple and clean.

3. Process is relatively simple, requires less equipment, and the solution can be reused, reducing costs.

Disadvantages:

1. The thickness of the passivation film is limited and less effective compared to processes like powder or oil spraying.

2. The appearance effect is relatively single, mainly white, and cannot meet requirements for color diversity without additional treatments.

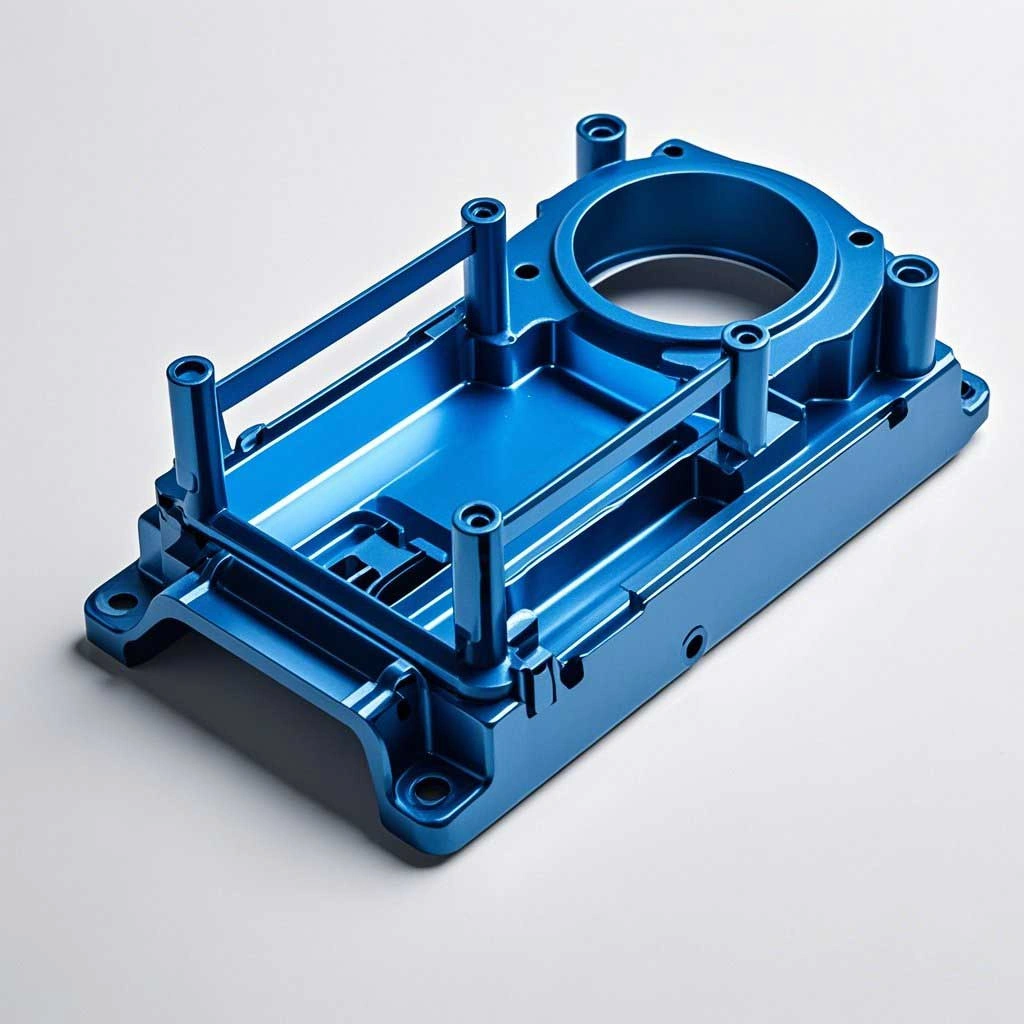

III. Powder Spraying

Applicable Scenarios:

1. Suitable for products with high durability and wear resistance requirements, such as outdoor shells.

2. Products requiring color diversity, such as decorative covers or panels.

|

|

Advantages:

1. Provides color diversity to meet personalized customer needs.

2. Good durability, wear resistance, and corrosion resistance for long-term protection.

3. Cost is lower compared to oil spraying.

Disadvantages:

1. For complex die-castings, coating uniformity may be an issue and requires optimization.

2. Appearance is not as glossy as oil spraying.

IV. Oil Spraying

Applicable Scenarios:

1. Chosen for high-end product shells and ornaments requiring gloss, metallic texture, or pearlescent effects.

2. Provides waterproof and moisture-proof protection.

|

|

Advantages:

1. Provides diverse colors to meet customized needs.

2. Creates a smooth, uniform film with improved waterproof and insulating properties.

Disadvantages:

1. Solvents may affect the environment and health, requiring proper safety measures.

2. Slightly less durable than powder spraying; may fade or peel after long-term use.

Conclusion

In conclusion, there are multiple choices for the surface treatment processes of aluminum die-cast products. The most suitable process should be chosen based on application scenarios, required functions, and performance expectations. Our die casting services team can provide customized solutions to meet your needs.