As is well known, aluminum alloy die castings are currently widely used in products of various industries. Most of them have specific decorative requirements, such as lighting components, furniture fittings, electronic equipment accessories, architectural decoration, bathroom accessories, toys, etc. Therefore, relatively high requirements are imposed on the surface quality of die castings, and good surface treatment performance is also required. The most common defect in aluminum alloy die castings is surface blistering. Generally, it can be detected right after die casting, or it may also become evident after polishing or further processing. The reasons for the formation of bubbles are mainly as follows:

I. Excessively High or Low Mold Temperature

During the production process, if the mold temperature is either too high or too low, it is likely to cause blisters on the surface of the die casting. When the mold temperature is too high, the solidification speed of the alloy liquid in the mold slows down, making it easy for gases to be entrapped, thus resulting in blistering. On the other hand, when the mold temperature is too low, the fluidity of the alloy liquid in the mold deteriorates, and gases may not be able to be discharged promptly, which can also lead to blistering formation.

II. Unreasonable Die Casting Process Parameters

During the production process, the debugging parameters of die casting are of great importance. When the parameters are unreasonable, blisters may form on the surface of the die casting.

1. Insufficient injection pressure fails to fully compact the alloy liquid, and gases cannot be effectively discharged, which may lead to blistering.

2. If the die casting speed is too fast, turbulent flow will be generated in the cavity by the alloy liquid, entrapping gases and possibly resulting in blistering.

3. If the holding pressure time is too short, the die casting will not receive sufficient pressure during the solidification process, and gases may easily precipitate from the alloy liquid, forming blisters.

III. Problems with the Alloy Liquid

The alloy liquid may contain excessive amounts of gases, such as oxygen and hydrogen. If these gases cannot be discharged entirely during the die-casting process, blisters will form in the die-cast part. In addition, when the temperature of the alloy liquid is either too high or too low, it affects the solubility and discharge speed of the gases, which may lead to blister formation.

IV. Improper Use of Release Agents

During the production process, release agents may also be a crucial factor in the formation of blisters. If the quality of the release agent is poor, it may react with the alloy liquid, thereby forming blisters. Additionally, if the release agent is sprayed too much or unevenly, gases may be generated during the die casting process, causing the die casting to blister.

Conclusion

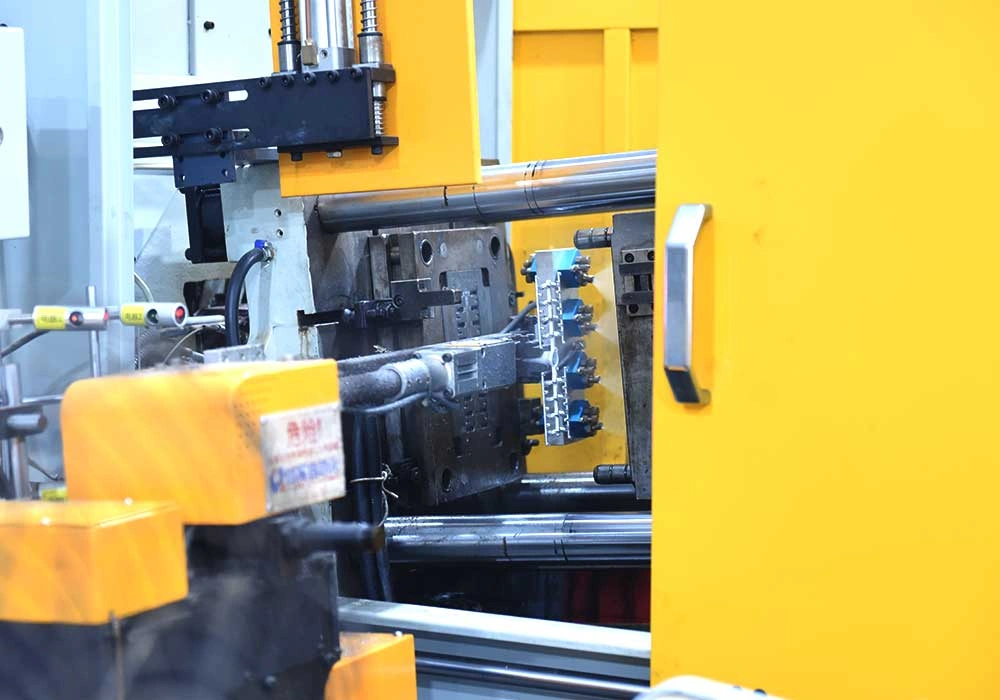

In conclusion, there are multiple reasons for the surface blistering of aluminum die castings. During the production process, we must carefully control each aspect to minimize the occurrence of blistering, increase the yield rate of die castings, and reduce production loss costs. As a professional die casting manufacturer, Shine-Choose provides technical support and process optimization to help customers achieve higher quality and efficiency.