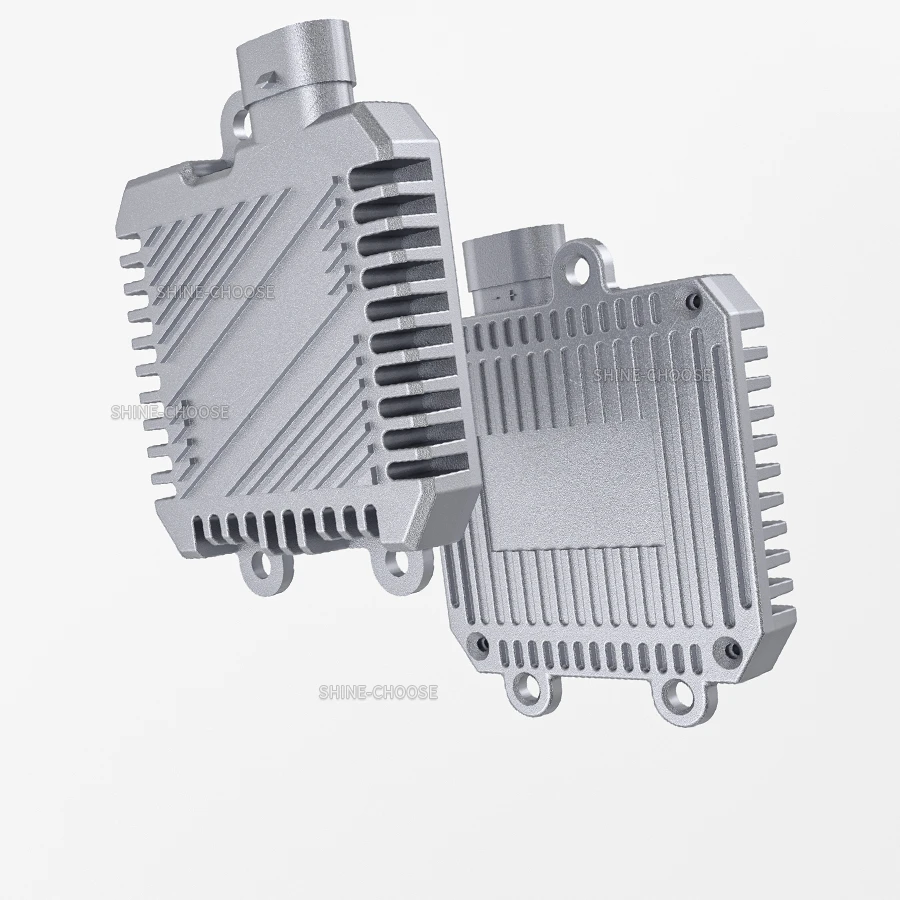

Precision Die Casting Process

From design to product, each step is refined to guarantee superior quality and performance.Die-Casting Mold Design

Alloy Melting

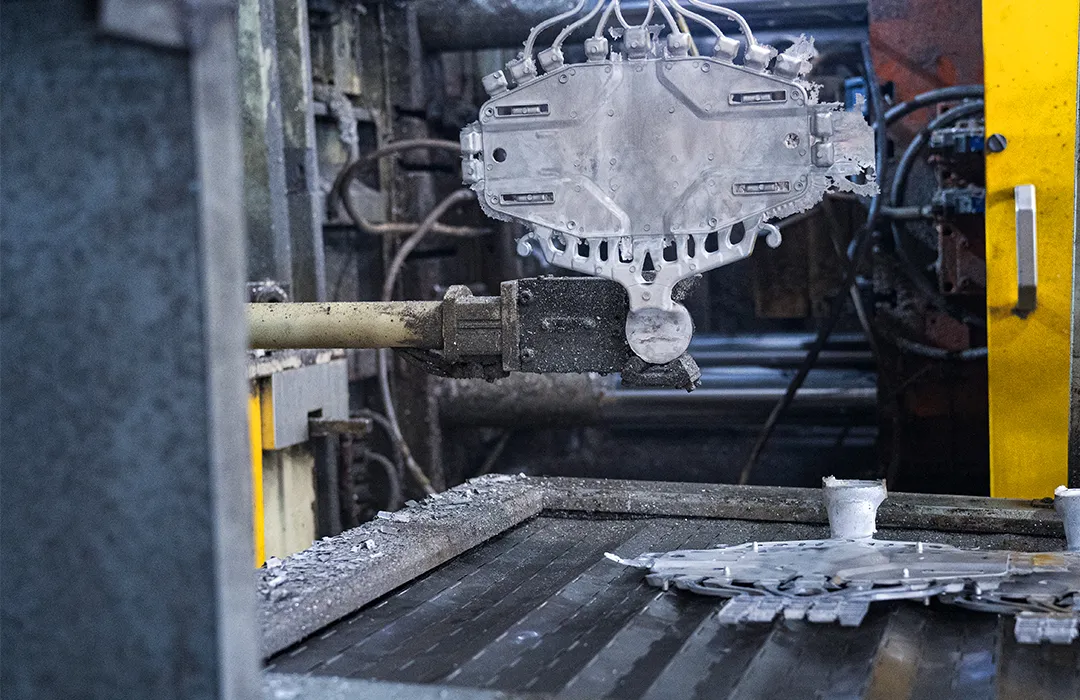

Die Casting Forming

Die-Cast Part Deflashing

Precision CNC Machining

Surface Treatment & Coating

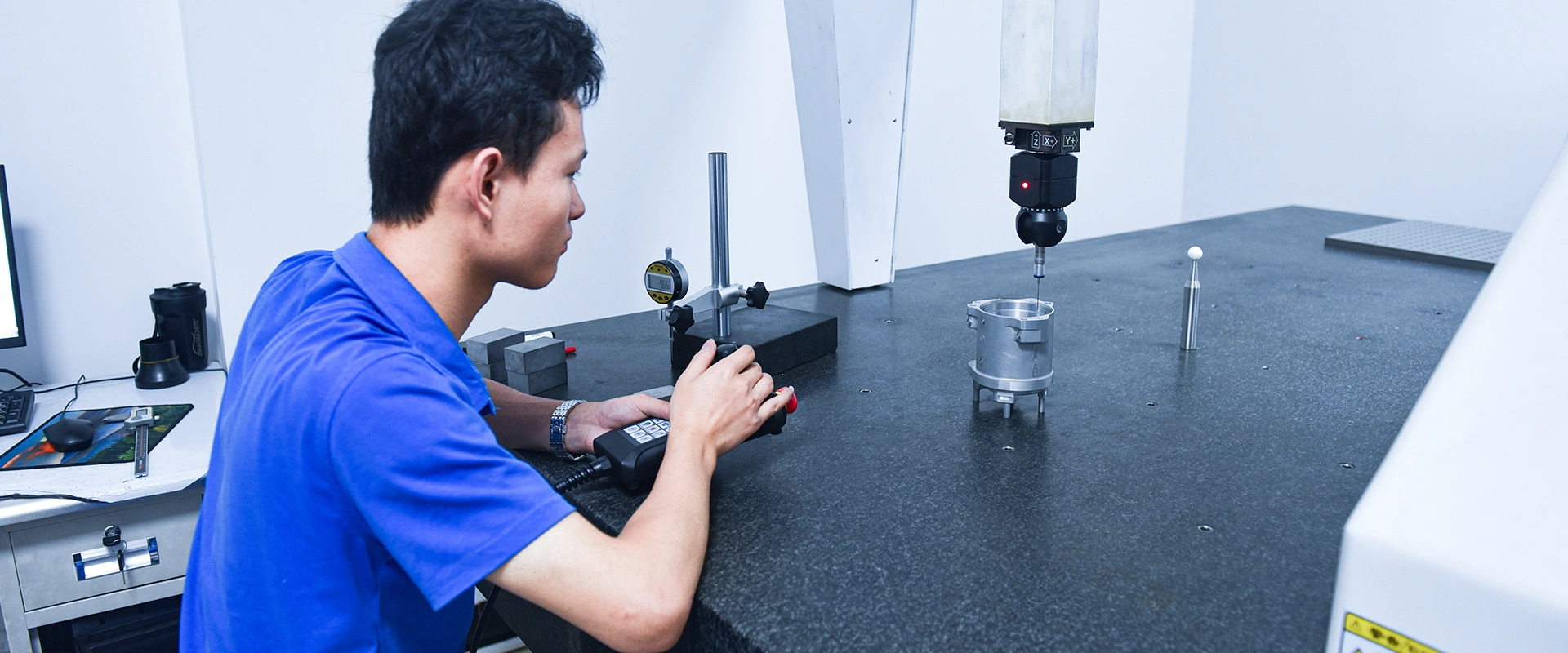

Quality Control (QC)

1

Die-Casting Mold Design

2

Alloy Melting

3

Die Casting Forming

4

Die-Cast Part Deflashing

5

Precision CNC Machining

6

Surface Treatment & Coating

7

Quality Control (QC)

Precision Die Casting Process

Contact UsDie-Casting Tonnage Range

88 - 2000T

From small to large die-Cast parts, covered

Maximum Die-Casting Mold Size

1800×1200mm

Capable of large, complex structural part production

Maximum Die-Cast Part Dimensions

1500×800mm

No splicing required; length and weight aren’t constrained.

Annual Throughput

15000000Pieces

High efficiency for large-scale production runs.

Surface Decoration

Read MoreQuality Management System Environmental Management System Automotive Quality Management Standard SGS Certification

ISO 9001

ISO 14001

IATF 16949

SGS

Delivery and Service Assurance

Customized die-casting solutions for diverse industries, driving customer success

- Flexible MOQ (Min. 2000 pcs)

- Quick Mold Adjustment & Flexible Production

- End-to-End Logistics & Customs Support

- Quality Warranty & Technical Support

3

Sampling 3 working days

2

Mold making 2 weeks

15

Mass production 15 working days